2025 Guide: How to Choose the Right Vegetable Processing Machine for Your Needs

Choosing the right vegetable processing machine is crucial for maximizing efficiency and ensuring quality in the processing industry. As an industry expert, Dr. Emily Carter, a renowned authority in food technology, emphasizes, "Selecting the appropriate equipment can significantly enhance both productivity and the final product's quality. It's not just about speed; it's about finding a machine that meets your specific processing needs."

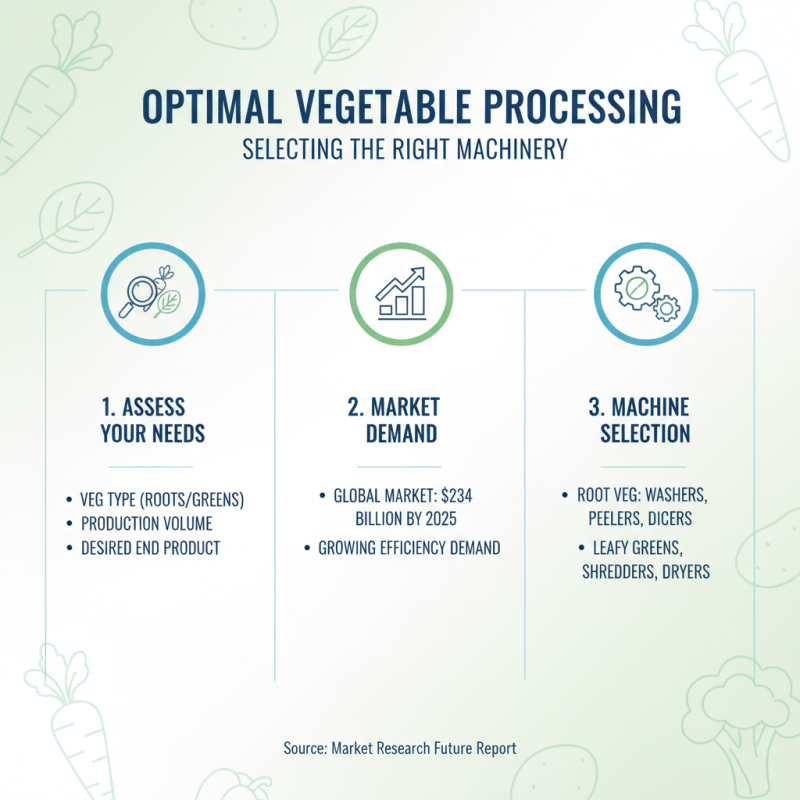

In today’s market, with an array of options available, making an informed decision can be overwhelming. Factors such as the type of vegetables, the scale of processing, and the desired end product play vital roles in determining which vegetable processing machine will be the most effective for your operations. Understanding the various capabilities and features of these machines can lead to improved operational efficiency and product consistency, ultimately benefiting your bottom line.

As we delve into this comprehensive guide, we will explore key considerations to keep in mind when selecting a vegetable processing machine. From understanding the technical specifications to evaluating the latest technological advancements, this guide aims to equip you with the knowledge necessary to make a well-informed choice tailored to your unique processing needs.

Understanding Your Vegetable Processing Needs

Understanding your vegetable processing needs is crucial for selecting the appropriate machinery that aligns with your production goals. According to a report by Market Research Future, the global vegetable processing market is projected to reach USD 234 billion by 2025, reflecting a growing demand for efficient processing solutions. Companies looking to invest in vegetable processing machines must first evaluate their specific requirements, including the type of vegetables they will process, the volume of production, and the desired end products. For instance, processing root vegetables like carrots and potatoes requires different machines compared to leafy greens like spinach.

Furthermore, analyzing production capacity and automation levels is essential. Data from the Food and Agriculture Organization indicates that automated processing can increase efficiency by up to 40%, which significantly impacts productivity and labor costs. Selecting equipment that accommodates future scalability is also advisable; many processors are exploring multi-functional machines to maximize flexibility with different vegetable types. Ultimately, a thorough assessment of processing needs ensures that the investment made in machinery aligns with both current and future operational objectives, fostering growth in a competitive market.

Types of Vegetable Processing Machines Available

When selecting the right vegetable processing machine, understanding the various types available is essential. One common type is the vegetable cutter, designed for slicing, julienning, or dicing vegetables efficiently. These machines come in manual and automatic versions, allowing for flexibility based on the scale of production. Cutters often include adjustable settings to achieve different thicknesses, making them suitable for diverse culinary requirements in restaurants and food processing facilities.

Another significant category includes vegetable peelers and washers, which help in preparing vegetables by removing skins and cleaning them thoroughly. These machines can range from simple manual peelers to more advanced automated washers that use water and air to ensure a proper clean. In larger operations, batch processing machines may be used, where vegetables are processed in large quantities, enhancing efficiency and consistency.

Lastly, there are specialized machines such as vegetable blanched and dehydrators, tailored for specific processing needs. Blanchers quickly cook vegetables to retain their color and nutrients before freezing or packaging, while dehydrators remove moisture, extending shelf life. Understanding these varieties allows businesses to make informed decisions tailored to their specific processing needs and target market.

Key Features to Consider When Selecting a Machine

When selecting a vegetable processing machine, it is crucial to consider several key features that will ensure the equipment meets your specific needs. First and foremost, assessing the capacity of the machine is vital; it should align with your expected processing volume. Whether you are operating on a small scale or looking to meet high demand, the machine’s output capacity should effectively handle the volume of vegetables you plan to process. Additionally, evaluate the machine's speed and efficiency, as these factors can greatly influence overall productivity.

Another important aspect to consider is the range of functionalities the machine offers. Some machines are designed for specific tasks such as cutting, peeling, or dicing, while others may provide multifunctional capabilities. Depending on your processing requirements, you should identify whether you need a specialized tool or a versatile machine that can perform various operations. Furthermore, look for features related to ease of operation and maintenance, as user-friendly controls and accessible parts can significantly reduce downtime and operational challenges in the long run.

2025 Guide: Key Features to Consider When Selecting a Vegetable Processing Machine

This chart illustrates the key features to consider when choosing a vegetable processing machine. Each feature is rated on a scale of 1 to 10, with higher values indicating greater importance for effective processing.

Budgeting for Your Vegetable Processing Equipment

Budgeting for vegetable processing equipment is a critical step in ensuring the efficiency and profitability of your operations. When establishing a budget, it's vital to consider not only the initial purchase price but also the long-term costs associated with maintenance, repairs, and energy consumption. A well-planned budget can help you avoid unexpected expenses down the line, allowing for a smoother production process and greater flexibility in responding to market demands.

In addition to the cost of the equipment itself, businesses should evaluate potential financing options and the return on investment (ROI) anticipated from their machinery. It's prudent to assess how quickly the equipment can enhance productivity, reduce labor costs, and ultimately contribute to higher profit margins. By including these factors in your budget, you can make informed decisions that align with your business goals and ensure that you invest wisely in vegetable processing technology.

2025 Guide: How to Choose the Right Vegetable Processing Machine for Your Needs - Budgeting for Your Vegetable Processing Equipment

| Machine Type | Processing Capacity (kg/h) | Power Consumption (kW) | Estimated Cost ($) | Maintenance Level |

|---|---|---|---|---|

| Vegetable Washers | 500 | 5.5 | 3,000 | Low |

| Vegetable Cutters | 1000 | 4.0 | 5,000 | Medium |

| Peeling Machines | 800 | 3.5 | 4,200 | Medium |

| Blanchers | 600 | 6.0 | 7,000 | High |

| Packaging Machines | 1200 | 8.0 | 10,000 | Medium |

Maintenance and Support for Vegetable Processing Machines

When selecting a vegetable processing machine, it's crucial to prioritize maintenance and support to ensure long-lasting performance and efficiency. According to industry reports, over 30% of unscheduled downtimes in processing facilities are attributed to inadequate maintenance, leading to significant financial losses. Regular maintenance not only extends the lifespan of your equipment but also can improve processing efficiency by up to 20%. Implementing a proactive maintenance schedule that includes regular inspections, cleaning, and parts replacement is essential in safeguarding your investment and maximizing productivity.

Tips: Establish a routine maintenance checklist that covers daily, weekly, and monthly tasks. This should include checking for wear and tear, lubrication of moving parts, and ensuring all safety features are operational. Documenting maintenance activities can also help identify patterns that may indicate future issues, allowing you to address them before they escalate.

In addition to routine maintenance, having a strong support system in place is vital, particularly for troubleshooting and repairs. Nearly 45% of operators experience challenges when seeking replacement parts or technical support, which can lead to prolonged equipment downtime. Choose suppliers who offer robust customer support, including access to technicians and readily available spare parts. This not only helps to minimize disruptions in your processing line but also builds a reliable relationship with your equipment provider.

Related Posts

-

Innovative Uses for Bag in Box Filling Machines in Beverage Production

-

2025 How to Choose the Best Vegetable Processing Machine for Your Needs

-

2025 Top 10 Fruit Washers: Best Picks for Clean and Healthy Produce

-

Top Fruit Processing Equipment Trends to Watch in 2025

-

Top 10 Automatic Bag Fillers for Efficient Packaging Solutions

-

Top 10 Bag in Box Holders to Enhance Your Beverage Experience in 2023