To begin, the Fruit and Vegetable Washer Elevator Mill MAXIMILL 1000 washes and mills your products, transforming them into a mash ideal for pressing. This machine’s gentle process ensures integrity and minimizes wastage.

Following milling, the Belt Press POWERPRESS 300 extracts juice from the fruit mash with high efficiency, maintaining optimal yield and quality.

The extracted juice flows into the Juice Collection Tank with Pump, where it is temporarily stored before further processing.

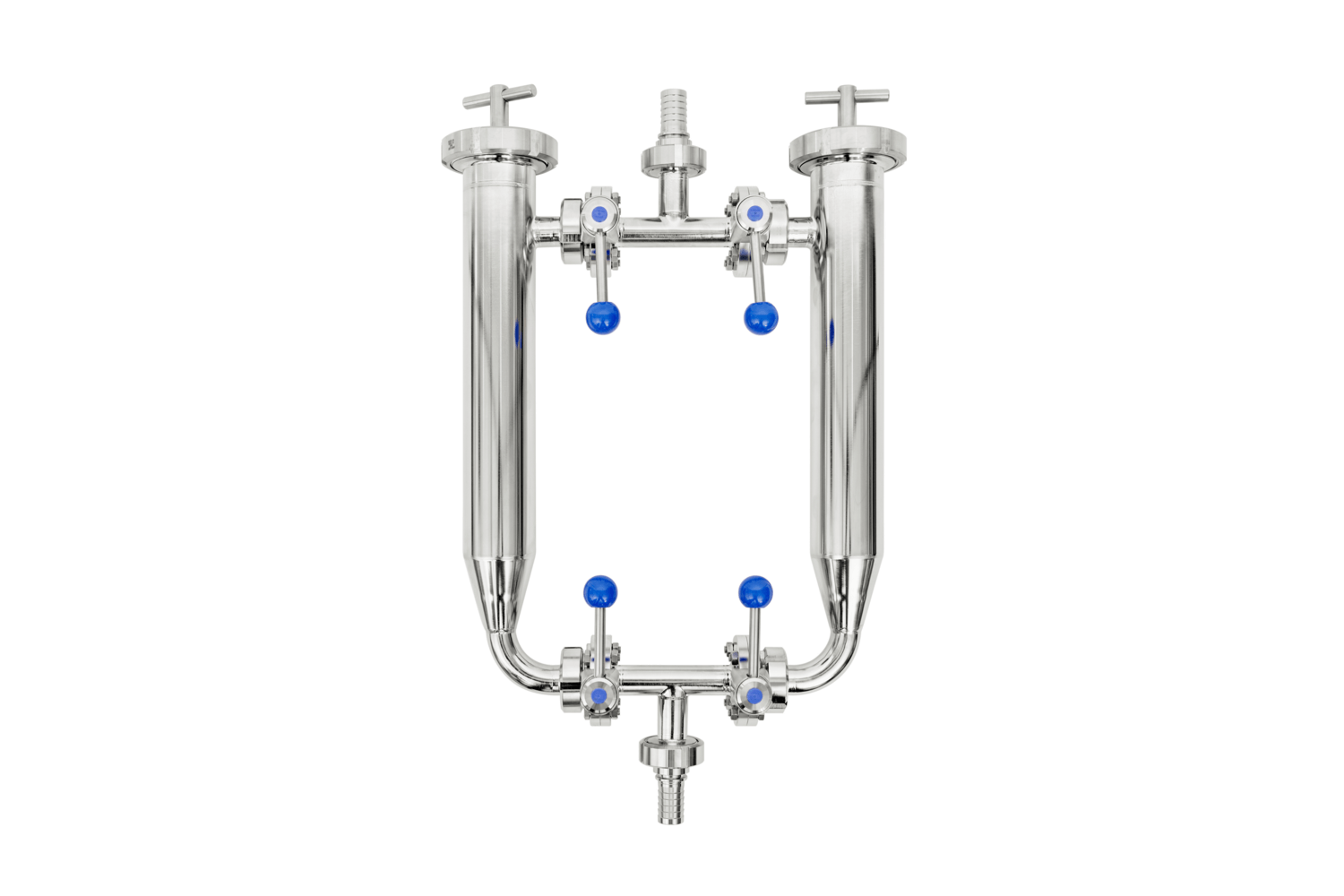

Next, the juice passes through the Stainless Steel Mechanical Double Juice Filter to remove particles.

After filtration, the juice enters the Pasteurizer-Filler ROCKET, where it undergoes pasteurization and is filled into bottles or Bag in Box packaging. This advanced equipment ensures safety and extends shelf life through precise temperature control.

In conclusion, our integrated 300 kg/h processing line ensures effortless operation, empowering businesses to consistently produce top-quality juices and other liquid products.