From Raw Produce to Bottled Juice

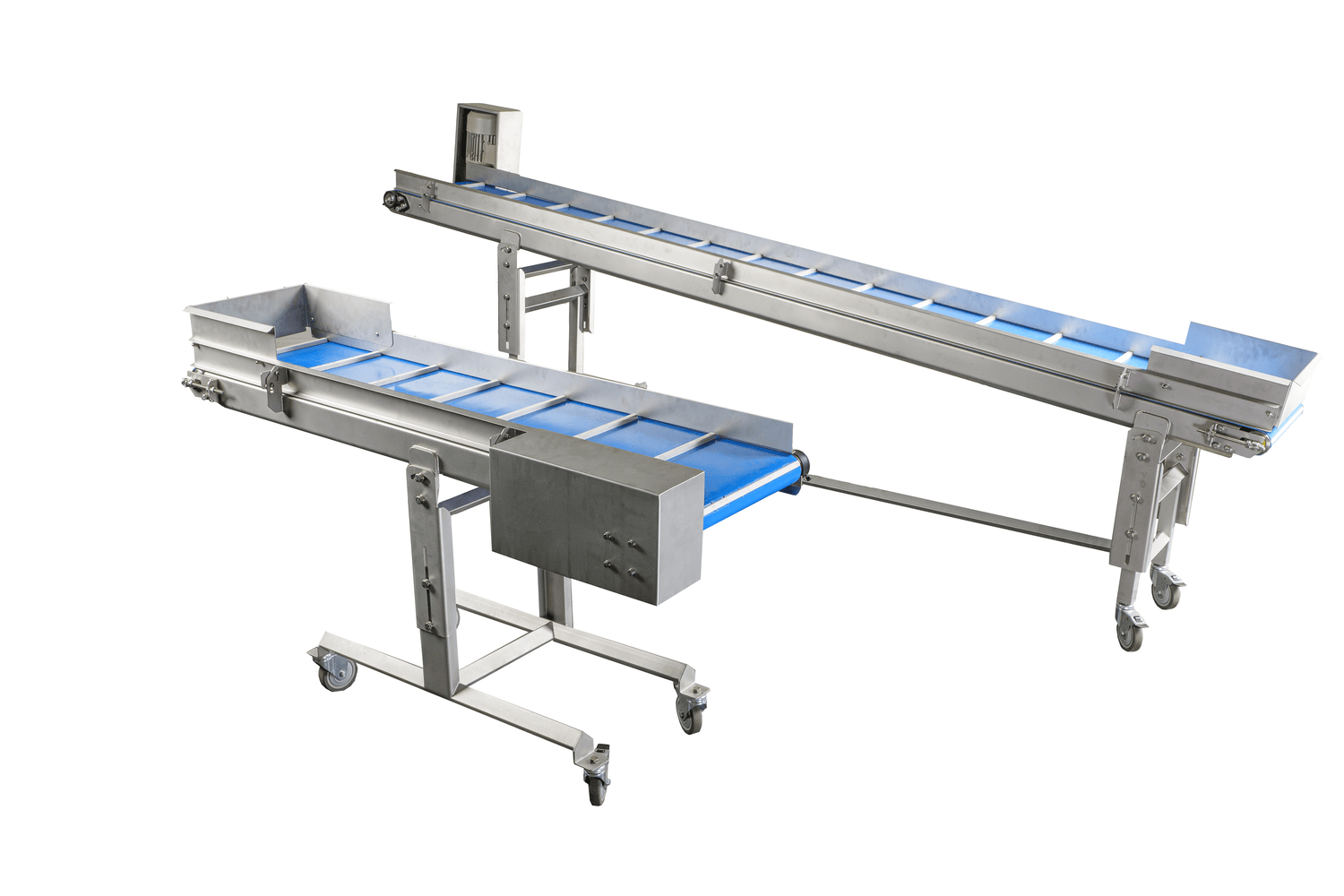

The cold press process begins with efficient fruit and vegetable intake using the Bin Tipper UNLOADER 800, which simplifies bulk handling. From there, the Sorting Conveyor allows for quick inspection and quality control, ensuring only top-grade produce enters the next stage.

Cleanliness is crucial, especially in raw juice workflows. That’s why we offer the Bubble Washer Elevator Mill AQUAMILL, which combines washing and milling into one compact system. It’s ideal for peeled or polished vegetables like beets and carrots, as well as apples, pears, and other soft fruits.

Maximum Yield with Gentle Extraction

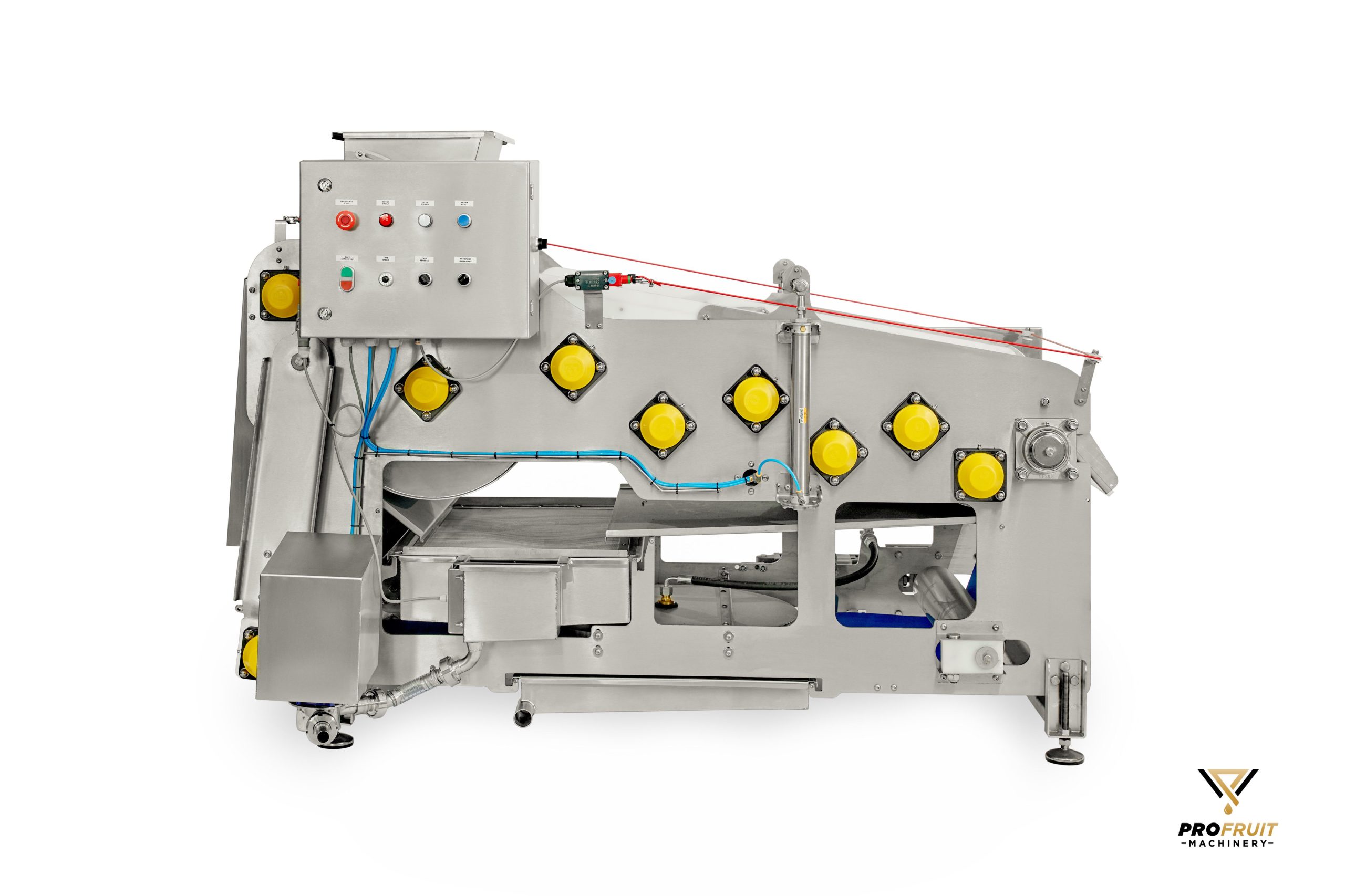

Our POWERPRESS belt presses (available in capacities from 400 to 3,000 kg/h) are the heart of the cold pressed juice processing line. These presses deliver exceptional juice yield while maintaining the freshness and nutritional value of raw ingredients.

For waste handling, the Screw Conveyor for Pressed Mash efficiently removes pomace, maintaining a clean production flow. Processed juice is collected in hygienic stainless steel tanks, ready for bottling or further treatment.

Flexible Filling Options

Final packaging is supported by ProFruit’s flexible solutions, including Manual Bottle Filler for small scale batches, automatic bottling equipment or Automatic Bag in Box Filler AUTOFLOW for commercial-scale filling.

Why Choose ProFruit?

- Complete cold pressed juice processing lines

- Belt presses designed for raw juice extraction

- Compatible equipment for washing, milling, pressing, and filling

- Proven reliability and expert support

With ProFruit’s cold pressed juice processing equipment, you’re not just buying machines – you’re investing in a smarter, more efficient way to grow your juice business. Our systems integrate seamlessly with complementary solutions like a belt press, Bag in Box filler, and every high-quality fruit processing machine you need for a streamlined, professional-grade production line.