From Raw Fruit to Finished Product

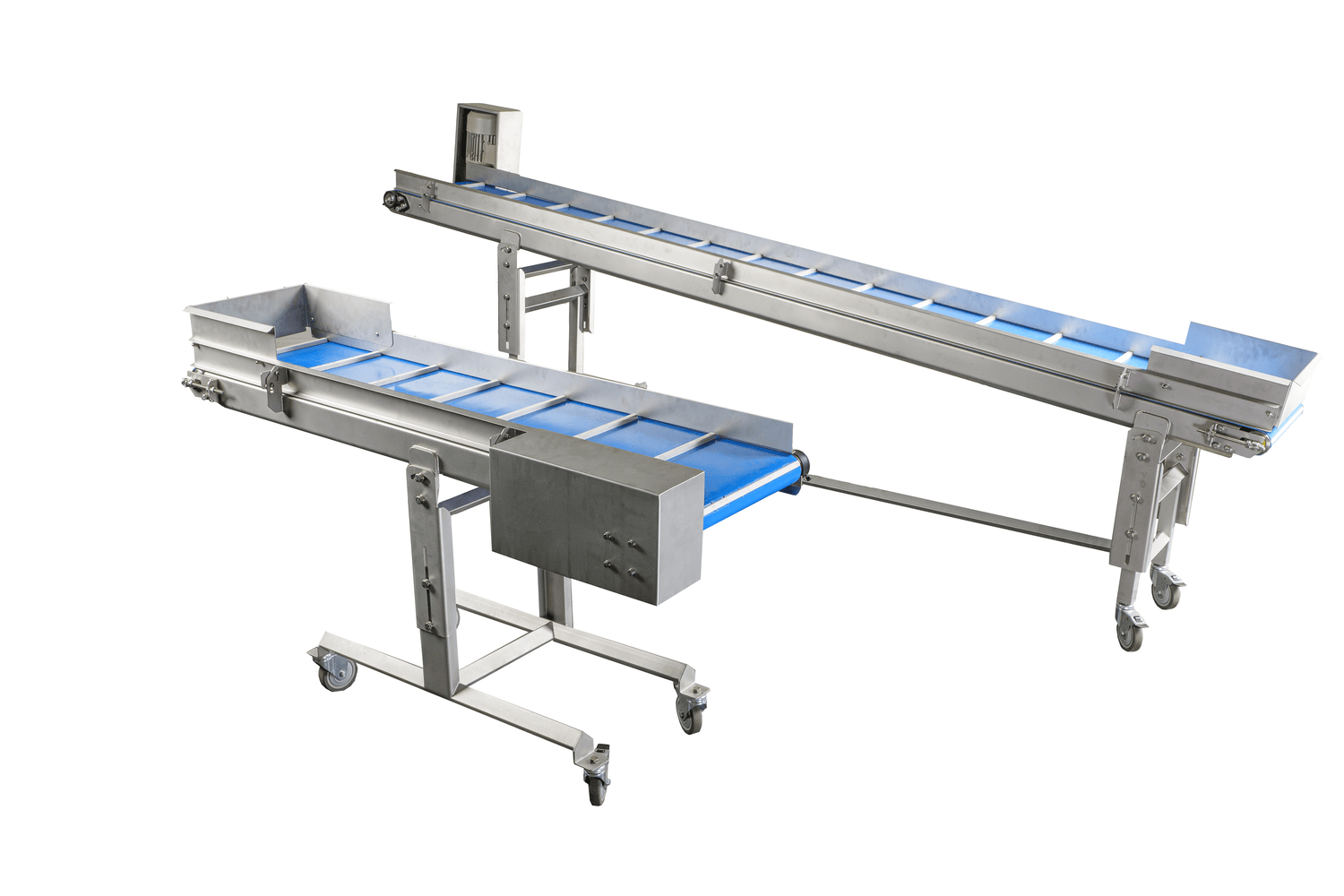

The process begins with the Bin Tipper UNLOADER 800, which safely unloads bulk fruit into the production line. Quality control is ensured on the Sorting Conveyor, where damaged or unripe fruit is removed.

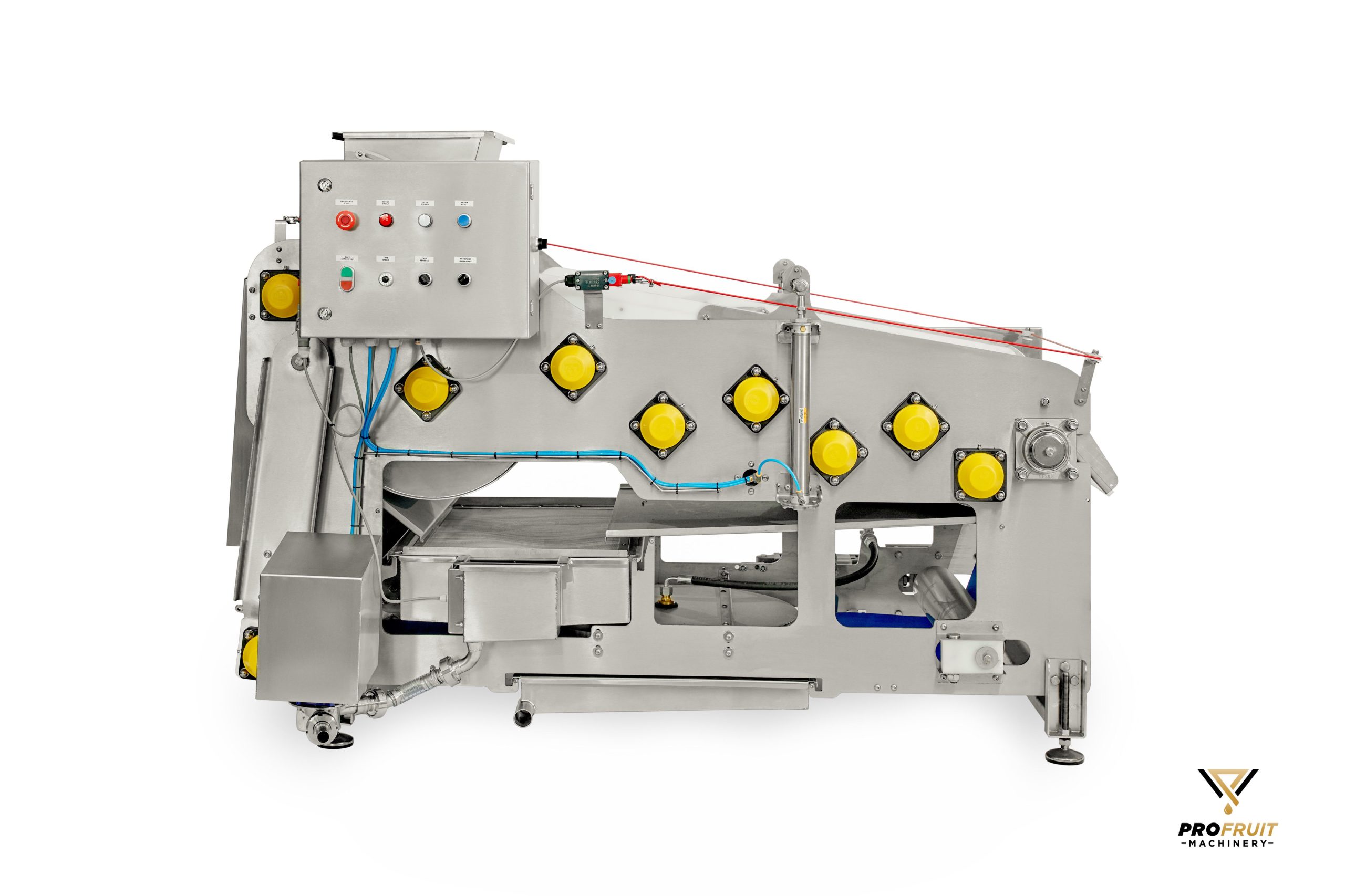

The selected fruit is washed using the Fruit and Vegetable Washer AQUA 3000, or for more delicate varieties, the Fruit Bubble Washer Elevator Mill AQUAMILL. Crushing is performed with the MAXIMILL 1000–3000 system, which combines washing, elevating, and milling in one machine. For fruits like mango that are not crushed due to the bitter skin, only washing is performed before further processing.

Destoning, Homogenization, and Pasteurization

Fruits like guava, mango, and pineapple require precise destoning and pulping. This is handled in one or two stages using the DESTONE 500–1000–2000 series, which separates skins and seeds while refining pulp into smooth purée.

Processed juice or purée is transferred to stainless steel tanks, then homogenized using the Juice Homogenizer to ensure uniform texture. For food safety and shelf life, the product is pasteurized using either the ECO HEAT Electric Pasteurizer or the HEAT Diesel/Gas Pasteurizer, depending on production requirements.

Final Packaging Made Easy

The final product is filled using the AUTOFLOW Automatic Bag in Box Filler, Vacuum Bottle Filler or automatic bottle filling systems, completing a smooth and professional-grade tropical fruit processing line.

With ProFruit’s tropical fruit systems, you gain reliable, food-grade equipment that includes every essential fruit processing machine for producing premium tropical juices and purées.