From Washing to Juice Extraction

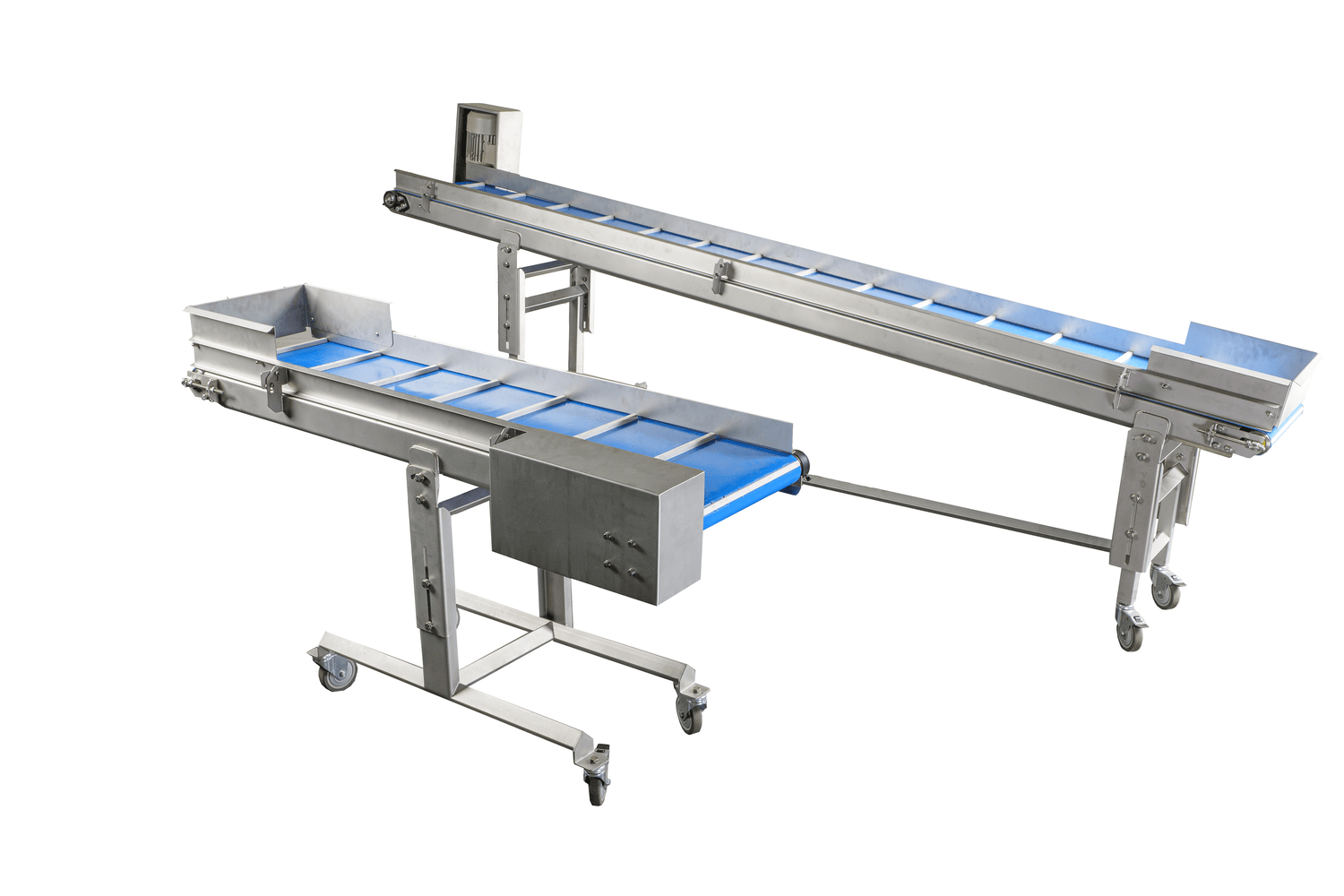

The process begins with the Bin Tipper UNLOADER 800, which streamlines bulk vegetable intake into the production line. Following this, the Sorting Conveyor allows the operator to inspect and manually remove any unsuitable produce, ensuring quality control before further processing. Peeled and polished root vegetables then proceed to the Bubble Washer Elevator Mill AQUAMILL, where they’re thoroughly washed and milled into a mash for pressing. The same system is also effective for leafy vegetables.

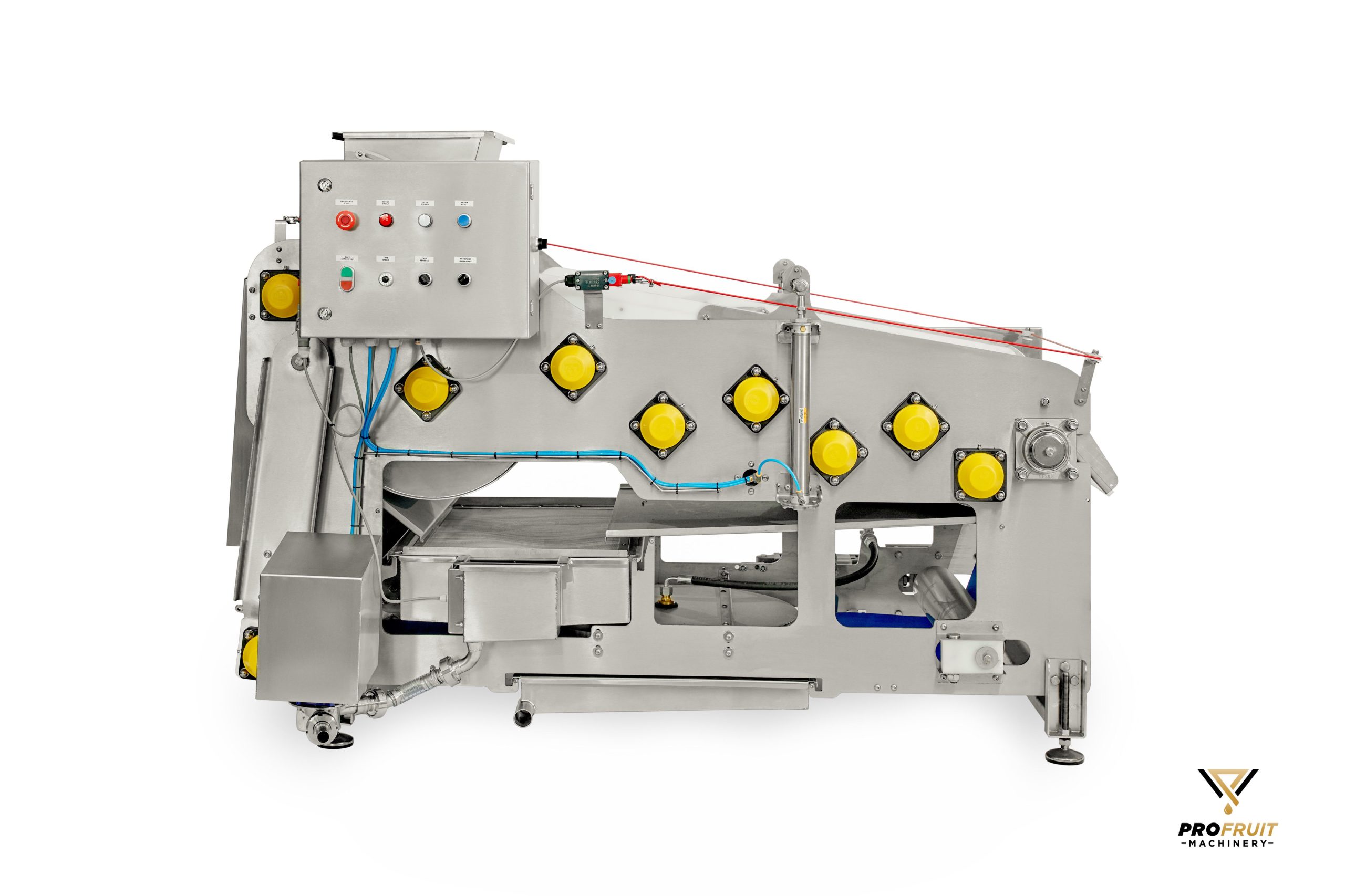

Juice extraction is performed using our high-capacity POWERPRESS Belt Presses, available in models from 400 to 3,000 kg/h. These presses maintain the natural flavor and nutrients of the vegetables while achieving excellent yield. Waste mash is efficiently managed with the Screw Conveyor for Pressed Mash, optimizing cleanliness and minimizing manual handling.

Pasteurization, Blending, and Bottling

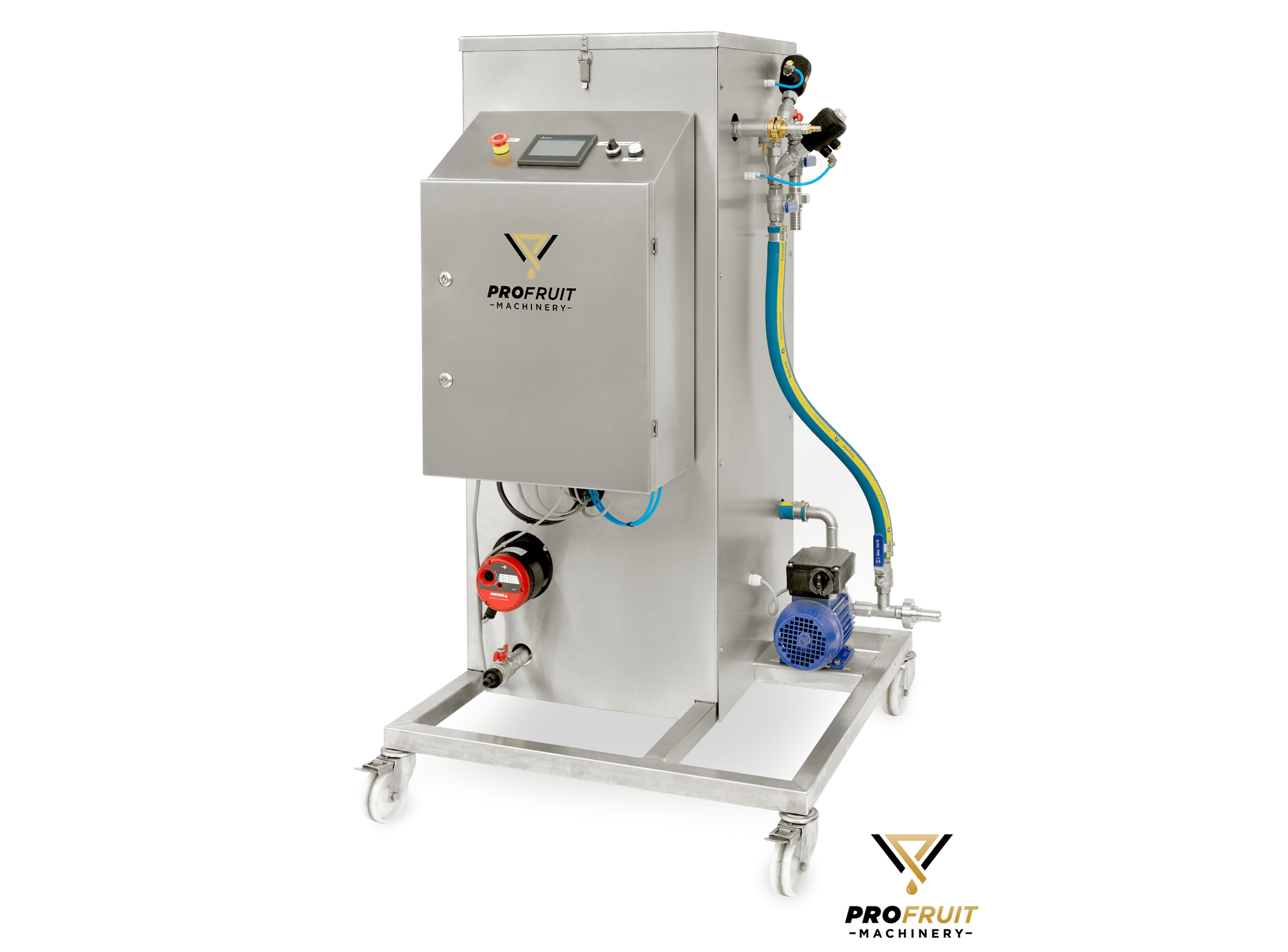

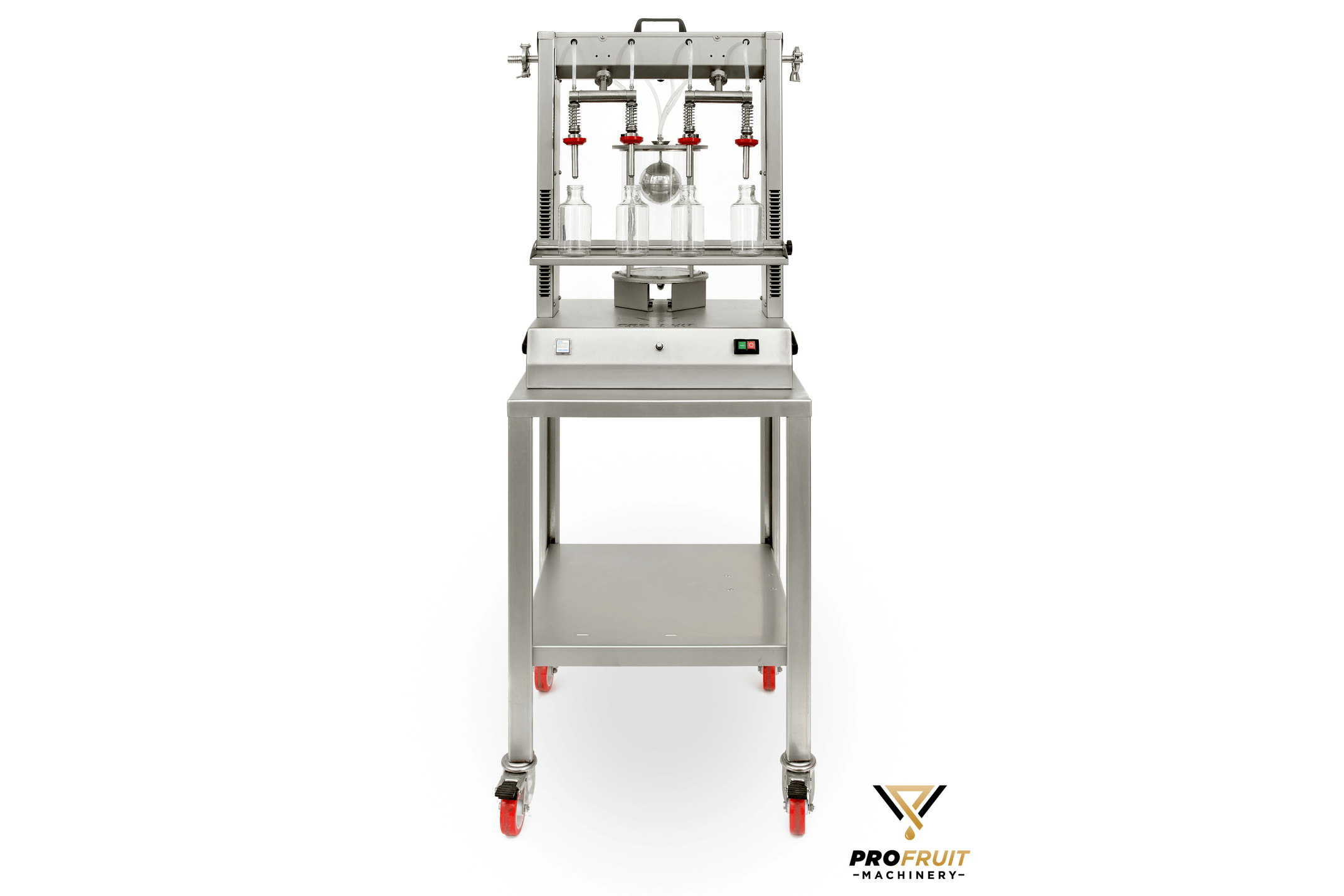

Processed vegetable juice can be collected and blended in stainless steel tanks, often combined with fruit juices like apple or orange to balance taste and enhance preservation. For shelf-stable products, ProFruit’s ECO HEAT and HEAT pasteurizers deliver precise heat treatment. If the juice is meant for raw consumption, it can go straight to bottling via the Manual Bottle Filler GRAVITY, Vacuum Bottle Filler or automatic bottling systems.

Why Choose ProFruit?

- Complete systems for both root and leafy vegetable processing

- Integrated juice extraction, pasteurization, and filling solutions

- Efficient, hygienic, and space-optimized equipment designs

- Proven reliability for commercial vegetable juice production

With ProFruit, you’re equipped to handle vegetable processing at every stage – from raw intake to bottled product – with performance and confidence.