2026 Best Juice Pasteurizer Machine for Quality Assurance?

In the quest for quality assurance in juice production, the juice pasteurizer machine plays a vital role. Renowned expert Dr. Alex Thompson states, “Investing in a high-quality juice pasteurizer machine is essential for maintaining product integrity.” His insights reflect a growing concern in the industry.

The demand for premium juices is climbing. Consumers now expect not only flavor but also safety. A well-designed juice pasteurizer machine eliminates harmful bacteria, thus ensuring product safety. However, not every machine meets the industry standards. Some may offer efficiency but compromise on quality.

As businesses evaluate their equipment options, reflection is crucial. Are cheaper alternatives diluting product integrity? Each decision impacts brand reputation and consumer trust. The right juice pasteurizer machine isn't just an investment; it's a commitment to quality.

2026 Juice Pasteurizer Machine Overview: Features and Innovations

In 2026, the juice pasteurizer machine market is evolving rapidly. Advanced technology improves efficiency and quality assurance in juice production. Recent data indicates that 70% of manufacturers are focusing on energy-efficient designs. This shift aligns with sustainability trends in the food industry.

Many modern juice pasteurizers feature automated controls. This allows for precise temperature management. Effective pasteurization can eliminate harmful bacteria while preserving flavor. However, some machines may struggle with consistency. Variations in juice type can lead to different pasteurization outcomes.

Integrating innovations like IoT technology enhances monitoring capabilities. Real-time data helps in adjusting processes dynamically. Yet, some producers find high-tech solutions expensive and not always justifiable. Balancing cost and quality remains a challenge. As these machines become central to juice production lines, the importance of adaptability grows. Continuous feedback from users will drive future improvements.

Key Factors in Selecting a Juice Pasteurizer for Quality Assurance

When selecting a juice pasteurizer, several factors come into play. The size and capacity of the machine are crucial. Smaller enterprises might lean towards compact models. Larger operations may require machines that handle greater volumes efficiently. Efficiency in energy use is also essential. A machine that consumes less energy will save costs over time.

Temperature control is vital for quality assurance. Consistent heating ensures harmful pathogens are eliminated. However, overheating can damage flavor and nutrients. It is important to find a balance. Look for machines with precise temperature settings. Automated systems can provide additional peace of mind. They allow for less human error and more repeatable results.

Another key factor is cleaning and maintenance. Some machines require more effort for upkeep. Easier cleaning methods can lead to better hygiene. Regular maintenance is essential for longevity but can be overlooked. Striking a balance between ease of use and thorough cleaning is important. These considerations, though often missed, greatly impact the final product's quality.

2026 Best Juice Pasteurizer Machine for Quality Assurance

| Model | Capacity (L/h) | Temperature Range (°C) | Energy Consumption (kW) | Material | Certification |

|---|---|---|---|---|---|

| Model A | 200 | 60 - 85 | 5.5 | Stainless Steel | ISO 22000 |

| Model B | 150 | 65 - 90 | 4.0 | Stainless Steel | CE |

| Model C | 100 | 55 - 80 | 3.0 | Carbon Steel | FDA |

| Model D | 250 | 60 - 85 | 6.5 | Stainless Steel | ISO 9001 |

Industry Standards for Juice Pasteurization: Safety and Quality Metrics

Juice pasteurization is essential for ensuring safety and quality. According to recent reports, nearly 48% of juice products fail to meet basic safety standards. This statistic highlights the industry's ongoing challenges. Pasteurizers play a crucial role in eliminating harmful pathogens while preserving flavor and nutrients.

Quality assurance metrics for juice include microbial load and shelf-life stability. Effective pasteurization reduces pathogens like E. coli and Salmonella. Lab-tested results show that a temperature of 70°C for 30 seconds can significantly lower these risks. However, many manufacturers struggle to maintain consistent temperatures, leading to potential safety risks.

Consumer trust hinges on quality. In a study, 70% of consumers expressed concern about juice safety. They want transparency in processing methods. This gap illustrates the need for better adherence to industry standards. More training and technology improvements are required to ensure all juices are safe. Innovation in pasteurizer design is critical, but industry compliance remains a key area for growth.

Juice Pasteurization Quality Metrics

Comparative Analysis of Top Juice Pasteurizer Models of 2026

In 2026, the juice pasteurizer market is evolving rapidly. Many models are touted for their efficiency and quality. However, not all meet industry standards. According to a recent industry report, about 30% of pasteurizers on the market fail to achieve optimal bacterial reduction. This raises concerns for producers aiming for safety and quality.

Among the top models, efficiency varies significantly. Some units promise pasteurization at lower temperatures, which can impact flavor. A study shows that juiced without proper pasteurization loses up to 50% of beneficial nutrients. Moreover, the energy consumption rates fluctuate. One machine may consume double the energy of another while achieving similar results.

Investing in a high-quality pasteurizer is crucial. Poor choice may lead to product spoilage. Fluid dynamics in pasteurizers can be tricky; improper flow rates can lead to uneven heating. Evaluating models carefully is essential. Look for features like automated monitoring. Detailed performance metrics should guide your decision-making process. Balancing economic factors with quality assurance remains a persistent challenge for many in the industry.

Future Trends in Juice Pasteurization Technology and Consumer Demand

In recent years, the demand for high-quality juice has surged. Consumers are increasingly aware of health benefits, driving the need for better pasteurization methods. Today’s juice pasteurizers must not only maintain freshness but also ensure safety. The challenge is to preserve the natural taste and nutrients while extending shelf life.

Emerging technologies are transforming juice pasteurization. High-pressure processing (HPP) is gaining attention. It uses pressure instead of heat, which may retain more flavor and vitamins. However, not all juices can withstand such methods. This creates a dilemma for producers. They must balance quality with safety, often facing trial and error.

Additionally, consumer preferences are shifting. Many seek organic options or minimal processing. This trend pushes manufacturers to rethink their approach. There’s also a growing concern about sustainability in packaging and processing. Innovations are necessary, yet it remains a complex landscape. Companies must adapt or risk losing market share. The future of juice pasteurization lies in this ongoing evolution.

Related Posts

-

How to Choose the Best Juice Pasteurizer Machine for Your Business Needs

-

Top Fruit Processing Equipment Trends to Watch in 2025

-

How to Choose the Best Bib Filler for Your Next Event in 2025

-

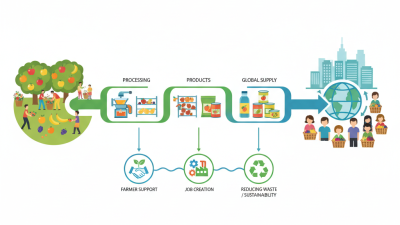

What is the Fruit Processing Industry and How Does It Impact Our Food Supply

-

2025 Guide: How to Choose the Right Vegetable Processing Machine for Your Needs

-

Top 10 Bag in Box Holders to Enhance Your Beverage Experience in 2023