How to Choose the Right Automatic Box Filling Machine for Your Business?

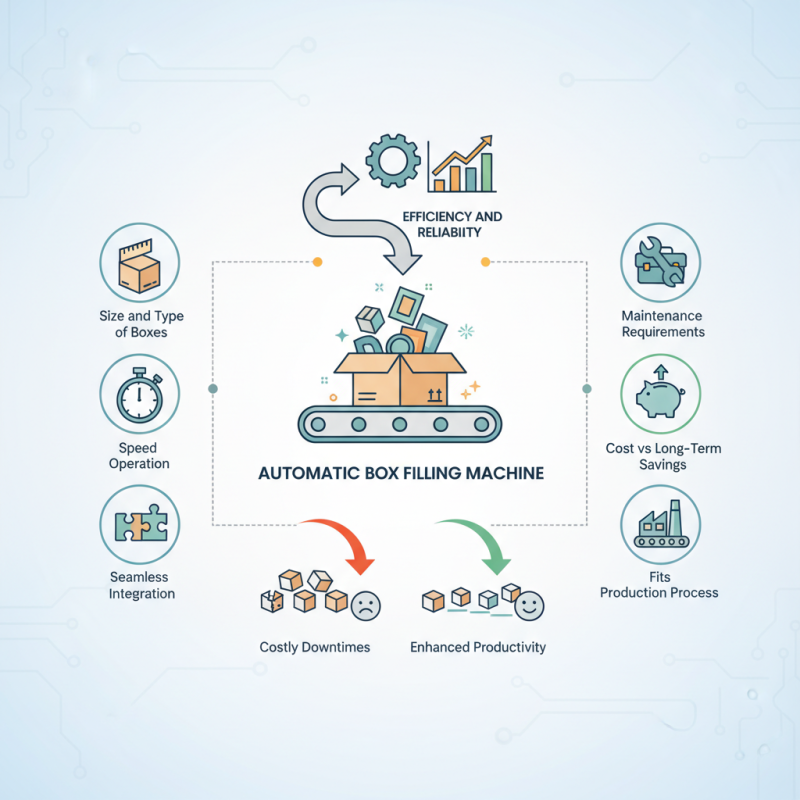

When selecting an automatic box filling machine for your business, the decision can feel overwhelming. There are countless options on the market. Experts encourage businesses to understand their specific needs before making a choice. John Smith, a reputable industry expert, once said, "Choosing the right automatic box filling machine is not just about cost; it’s about efficiency and reliability."

It's essential to consider various factors. Think about the size and type of boxes you'll be using. The speed of operation is also crucial. An automatic box filling machine should integrate seamlessly into your existing production line. Unexpected downtimes can be costly and frustrating. Additionally, the machine's maintenance requirements must align with your operational capabilities.

Whether you are a startup or an established company, the right machine can greatly enhance productivity. Reflect on past choices and their impacts. Sometimes, spending more upfront saves money in the long run. The ideal machine should fit your production process, not hinder it.

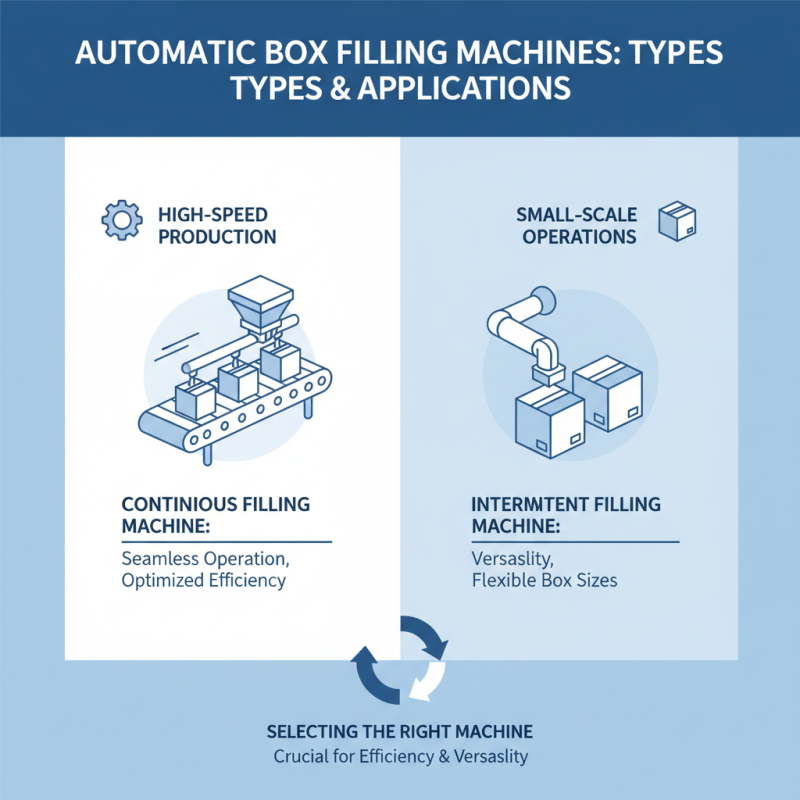

Understanding Different Types of Automatic Box Filling Machines

When selecting an automatic box filling machine, understanding the various types is crucial. These machines vary in design, functionality, and application. For industries requiring high speed, a continuous filling machine is ideal. It operates seamlessly, optimizing production efficiency. On the other hand, for small-scale operations, an intermittent filling machine can be more suitable. It offers versatility and flexibility for different box sizes.

Tips: Assess your production capacity first. Choose a machine that aligns with your output needs. Also, consider the types of products being filled. Flowable materials typically require gravity fillers, while thicker substances may need pump fillers.

Another type is the volumetric filling machine, which works by measuring a specific volume for each box. This method ensures consistency, though it may not suit every product. Many users appreciate the accuracy, but they must adjust settings frequently. Look out for such nuances. Evaluate how often the machine will need recalibration. It's important to reflect on ease of use. Complex machines can hinder productivity.

Tips: Always test a machine before purchasing. Understand its maintenance requirements and user interface. A complicated setup can lead to operational delays. Think about future business growth too. Your choice should not only meet current needs but also allow for expansion.

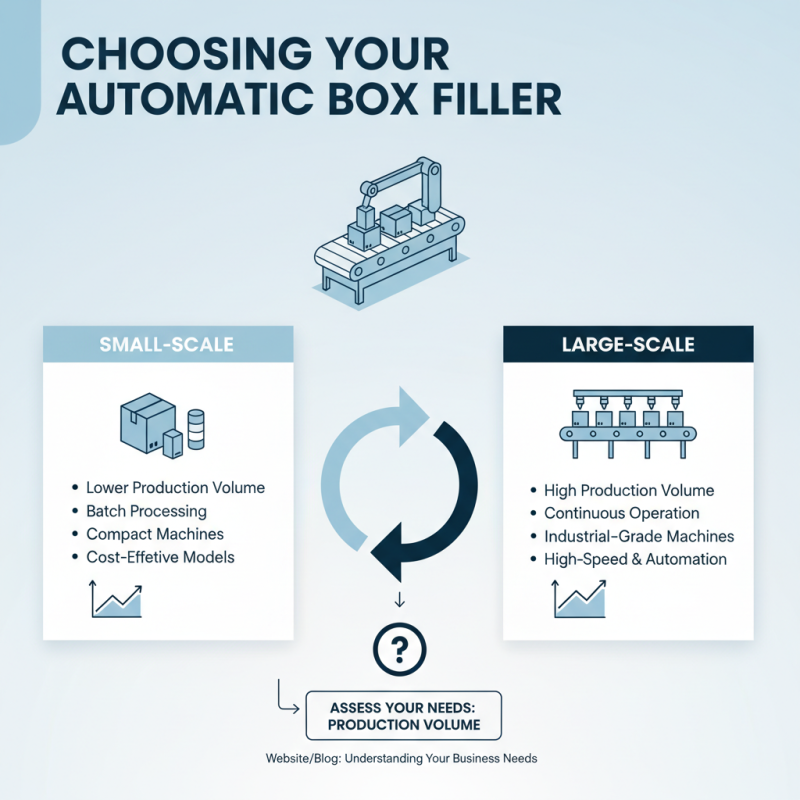

Assessing Your Business Needs and Production Volume

Choosing the right automatic box filling machine begins with understanding your business needs. You must assess your production volume first. Is your operation small-scale or large-scale? Knowing this will guide your decision.

If you produce a high volume of products, a robust machine is crucial. A slower machine may lead to bottlenecks, impacting efficiency. Pay attention to specifics, like speed and capacity. For smaller operations, a more compact model may suffice. But watch for limitations. It could become inadequate as your business grows.

Consider the types of products you’re filling. Different items may require distinct handling. Fragile products need gentle handling. For dense materials, ensure the machine can manage weight without issues. Evaluate your current workflow and identify any gaps. Reflect on your long-term goals and scalability. It’s essential not to rush this decision. Choosing the wrong machine can lead to costly setbacks.

Evaluating Machine Features and Specifications

When evaluating automatic box filling machines, focus on specific features. Look for adjustable filling volumes to suit various box sizes. This flexibility can save time and reduce waste. Some machines may not handle all product types well. Assess their compatibility with liquids, powders, or granules before making a choice.

Next, consider the speed of operation. Find a machine that fits your production rate. Some machines can fill boxes quickly, but they may lack precision. Fast does not always mean efficient. Moreover, the ease of maintenance should not be overlooked. Complicated machinery can lead to costly downtimes and repairs.

Always check user reviews or feedback for real-world insights. Companies often highlight their machines’ strengths, but weaknesses can be hidden. Asking other users about their experiences can provide valuable information. This will help you make a more informed decision. Pay attention to the energy efficiency of the machines as well. Energy costs can add up and impact your overall business expenses.

Comparing Costs and Budget Considerations

When selecting an automatic box filling machine, understanding costs is crucial. According to a recent industry report, businesses spend anywhere from $5,000 to $50,000 for these machines, depending on their complexity and features. The price can fluctuate based on production speed and material compatibility, making it essential to assess your specific needs.

Budget considerations often extend beyond the initial purchase price. Maintenance costs can accumulate, with estimates suggesting that annual expenses may range from 10% to 20% of the machine's total cost. This ongoing investment can influence cash flow and overall profitability. Additionally, consider the potential for production downtime during repairs, which may incur hidden costs.

While a cheaper machine may seem appealing, weigh the long-term implications. A low-cost option might lack the efficiency and reliability you need. These shortcomings can hurt your output and customer satisfaction. Look at total ownership costs rather than just the upfront price. This approach ensures your chosen machine aligns with your business goals and can adapt to future demands.

Researching Manufacturers and Customer Reviews

When looking for an automatic box filling machine, customer reviews are a goldmine of information. Many users share their direct experiences, highlighting both strengths and weaknesses. According to a recent study by The Packaging Machinery Manufacturers Institute (PMMI), about 70% of buyers refer to customer testimonials before making a decision. These reviews often reveal insights into machines' reliability and efficiency, which standard product descriptions might overlook.

Delving into specific feedback can uncover red flags. Some customers report issues with machine compatibility and maintenance challenges. For instance, 45% of users mentioned frequent need for technical support, indicating that some machines may not be as user-friendly as expected. Additionally, reviewers frequently discuss service after the sale, impacting their overall satisfaction. Those reflections help potential buyers gauge whether the manufacturer values long-term customer relationships.

Data from the International Packaging Association highlights that businesses investing in well-reviewed machinery see a 30% increase in operational efficiency. However, feedback can be mixed. Some users emphasize the importance of personal consulting for tailored solutions. It's evident that while numbers are vital, real user experiences can guide future investments, ensuring a machine that fits unique business needs.

How to Choose the Right Automatic Box Filling Machine for Your Business?

| Machine Type | Filling Method | Production Speed (boxes/min) | Box Size (L x W x H) | Price Range ($) | Customer Rating (1-5) |

|---|---|---|---|---|---|

| Vertical | Gravity Fill | 25 | 12" x 10" x 6" | 5,000 - 10,000 | 4.2 |

| Horizontal | Piston Fill | 30 | 14" x 12" x 8" | 8,000 - 15,000 | 4.5 |

| Automatic | Vacuum Fill | 20 | 10" x 10" x 10" | 10,000 - 20,000 | 4.0 |

| Semi-Automatic | Suction Fill | 15 | 16" x 12" x 6" | 3,000 - 7,000 | 3.8 |

| Rotary | Auger Fill | 40 | 12" x 12" x 8" | 15,000 - 25,000 | 4.8 |

Related Posts

-

Exploring the Versatility of Bib Bag in Box for Eco Friendly Packaging Solutions

-

2025 Guide: How to Choose the Right Vegetable Processing Machine for Your Needs

-

What is the Fruit Processing Industry and How Does It Impact Our Food Supply

-

Innovative Uses for Bag in Box Filling Machines in Beverage Production

-

2025's Top Vegetable Washers: Best Features and Buying Guide

-

What is a Pouch Filler and How Does it Work?