Why Choosing the Right Juice Processing Equipment Is Essential for Your Business

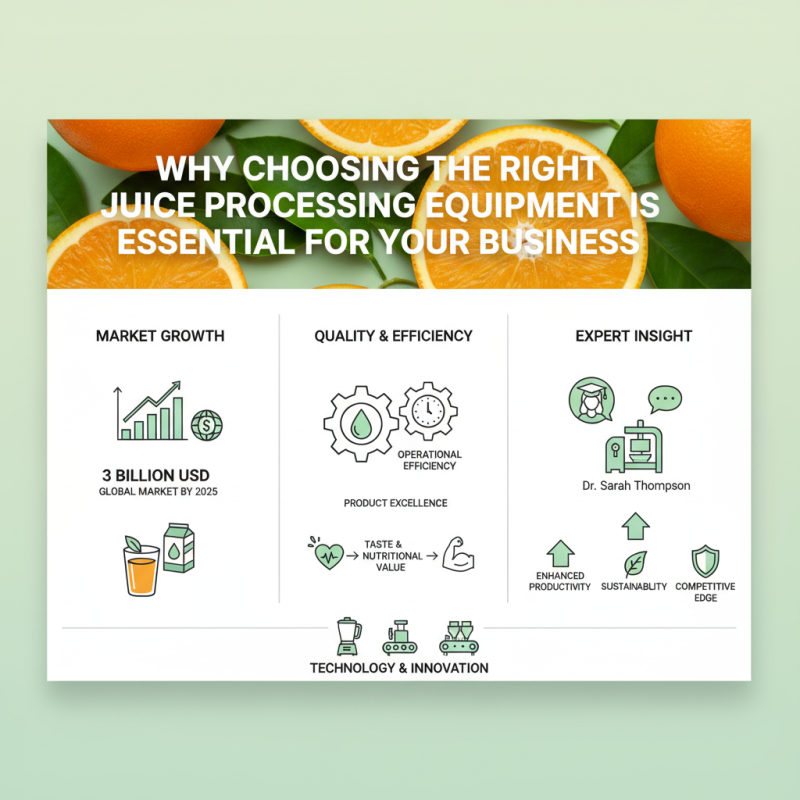

In the competitive landscape of the beverage industry, the quality of juice processing equipment plays a pivotal role in ensuring product excellence and operational efficiency. According to a recent report from the Beverage Industry Association, the global juice processing equipment market is expected to reach $3 billion by 2025, driven by an increasing demand for fresh and natural juice products. Selecting the appropriate equipment not only enhances productivity but also impacts the overall taste and nutritional value of the juice.

Industry expert Dr. Sarah Thompson, a renowned specialist in food processing technology, emphasizes the significance of investing in high-quality juice processing equipment, stating, "The right equipment is crucial for maintaining the integrity of fresh juice, as it directly influences both the quality of the end product and the efficiency of the production process." As businesses strive to meet consumer demands for healthy and organic options, understanding the importance of juice processing equipment becomes vital.

With advancements in technology, the evolution of juice processing equipment is reshaping the industry standards, ensuring that manufacturers can deliver premium products while minimizing waste and operational costs. This focus on high-performing machinery not only supports sustainability efforts but also enhances the competitive edge of juice brands in a saturated market.

Understanding the Importance of Juice Processing Equipment in the Industry

In the juice industry, the importance of selecting the right processing equipment cannot be overstated. Juice processing equipment plays a vital role in maintaining the quality, flavor, and nutritional value of the final product. With advances in technology, various types of equipment are available, each designed to cater to specific operational needs, from extraction to bottling. By investing in high-quality machinery, juice producers can enhance their efficiency, reduce waste, and ensure compliance with industry standards.

Moreover, the choice of processing equipment directly impacts production capacity and scalability. Businesses looking to grow must consider equipment that not only meets current demands but can also adapt to future needs. The right equipment can streamline operations, allowing for faster processing times and improved product consistency. This leads to higher customer satisfaction and brand loyalty, essential factors in a competitive market.

Ultimately, understanding the importance of juice processing equipment is crucial for ensuring operational excellence and achieving business success in the juice industry.

Key Factors to Consider When Selecting Juice Processing Machinery

When selecting juice processing machinery, several key factors significantly impact the efficiency and quality of your production. First, the type of juice you plan to produce plays a critical role in determining the machinery you need. Different fruits and vegetables require specific extraction methods and machine capabilities. For example, high-juice yield fruits like oranges may require different processing requirements compared to vegetables. Identifying your primary products can help narrow your options to the equipment that best serves your needs.

Another crucial factor is the scalability of the equipment. As your business grows, your production needs may change. Choosing machinery that can accommodate increased volumes or adapt to new product lines can save you from costly upgrades or replacements in the future. Moreover, consider the ease of maintenance and availability of spare parts for the equipment you select, as this can significantly affect downtime and operational efficiency. Investing in user-friendly machinery enhances productivity and allows staff to operate the equipment with minimal training, further contributing to a seamless production process.

Types of Juice Processing Equipment and Their Functions

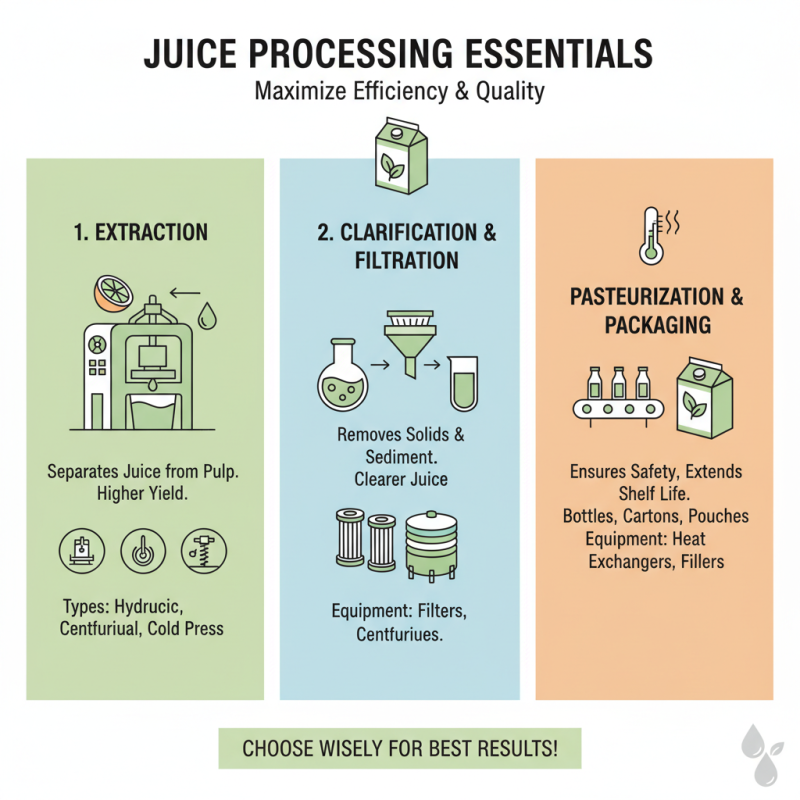

When it comes to juice processing, selecting the right equipment is vital for maximizing efficiency and maintaining product quality. Various types of juice processing equipment serve specific functions that streamline the production process. One of the most essential pieces of equipment is the extractor, which efficiently separates juice from pulp, ensuring a higher yield. Extractors come in different forms, such as hydraulic, centrifugal, and cold press, each offering distinct advantages depending on the juice type and desired flavor profile.

Another crucial component is the pasteurizer, which plays a key role in extending shelf life and ensuring food safety. Pasteurizers heat the juice to eliminate harmful microorganisms while preserving its nutritional value. Additionally, filtration systems are vital for achieving the desired clarity and consistency of the final product. These systems remove solids and impurities, resulting in a polished juice that appeals to consumers. As businesses scale their operations, investing in advanced processing equipment can significantly enhance their production capabilities, enabling them to meet market demand effectively.

Impact of Equipment Quality on Juice Quality and Business Success

The quality of juice processing equipment plays a pivotal role in determining the final product's quality and, by extension, the success of a juice business. According to industry reports, approximately 45% of juice quality issues can be traced back to inadequate processing equipment. This statistic highlights the importance of investing in high-quality machinery that not only preserves the nutritional value of the juice but also enhances its flavor and consistency. For instance, modern extraction technologies can significantly reduce oxidation during processing, leading to fresher and more vibrant end products that appeal to consumers.

Moreover, efficient juice processing equipment can enhance production efficiency and reduce waste, which is crucial in a competitive market. Data from the Beverage Industry shows that companies that have upgraded their equipment reported an increase in yield by up to 30%, enabling them to meet rising consumer demands without compromising on quality. Additionally, superior equipment often results in lower operational costs through reduced energy consumption and minimized downtime. Therefore, making the right choice in juice processing equipment is not only about quality but also translates into greater profitability and sustained business growth.

Cost-Benefit Analysis of Investing in Quality Juice Processing Equipment

Investing in quality juice processing equipment can significantly impact the bottom line of a juice business. While the initial costs may seem daunting, a thorough cost-benefit analysis reveals that high-quality equipment often leads to long-term savings. For instance, durable machinery tends to require less frequent repairs and maintenance, reducing downtime and associated costs. Additionally, efficient equipment can optimize the extraction process, yielding more juice from the same amount of raw material, thus enhancing profitability.

Moreover, the choice of processing equipment can also affect product quality and consistency. High-quality machinery often employs advanced technology that ensures better preservation of nutrients and flavors, which can lead to increased customer satisfaction and loyalty. Over time, a business that prioritizes quality processing can differentiate itself in a competitive market, allowing for premium pricing on its products. Ultimately, the investment in quality juice processing equipment not only enhances operational efficiency but also contributes to building a strong brand reputation, making it a wise financial decision for any juice business.

Cost-Benefit Analysis of Investing in Quality Juice Processing Equipment

This chart illustrates the cost-benefit analysis of investing in quality juice processing equipment. It highlights the initial investment cost versus the potential annual revenue increase and cost savings realized from using high-quality equipment over a 5-year period.

Related Posts

-

Exploring the Versatility of Bib Bag in Box for Eco Friendly Packaging Solutions

-

10 Essential Tips for Efficient Fruit and Vegetable Processing: Boosting Yield by 30%!

-

2025 Top 10 Bag in Box Machines for Efficient Packaging Solutions

-

Top 10 Automatic Bag Fillers for Efficient Packaging Solutions

-

Top 10 Bag in Box Holders to Enhance Your Beverage Experience in 2023

-

2025 Top 10 Fruit Washers: Best Picks for Clean and Healthy Produce