10 Essential Tips for Choosing a Bag in Box Filling Machine

In today's fast-paced packaging industry, selecting the right bag in box filling machine is crucial. According to a recent report by Smith Industry Insights, the demand for these machines is projected to grow by 8% annually. This increase reflects the shifting preferences towards eco-friendly packaging solutions. Experts emphasize the importance of choosing the right machinery to optimize production efficiency.

John Thompson, a senior engineer at PackTech Solutions, states, "The right filling machine can drastically reduce waste and increase productivity." However, many manufacturers struggle to navigate the selection process. They often overlook key features that can significantly impact operations. Industry reports indicate that 40% of companies feel dissatisfied with their filling machines after purchase. This dissatisfaction often stems from a lack of research or understanding of their specific needs.

Choosing a bag in box filling machine requires careful consideration. It's not just about initial costs; performance, maintenance, and scalability also matter. As the market evolves, staying informed can prevent costly mistakes and ensure long-term success. Making informed decisions paves the way for improved efficiency and sustainability in packaging.

Understanding Bag in Box Filling Machines: Types and Applications

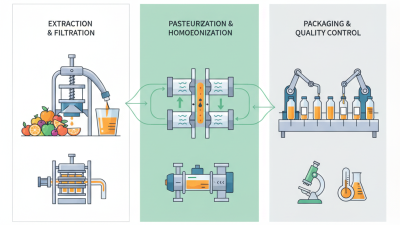

Bag in box filling machines are integral in many industries. These machines efficiently package liquids, such as juices, wines, and sauces. According to a report by MarketsandMarkets, the bag in box market is expected to grow by 4.1% annually, reaching over $3 billion by 2025. This growth is driven by the increasing demand for sustainable packaging options.

Different types of bag in box filling machines cater to various applications. For example, gravity fillers work well for low-viscosity liquids. They are simple but can lead to spills if not monitored correctly. On the other hand, pump fillers are more versatile. They can handle thicker liquids, but require precise calibration. An imbalance can lead to overfilling or underfilling.

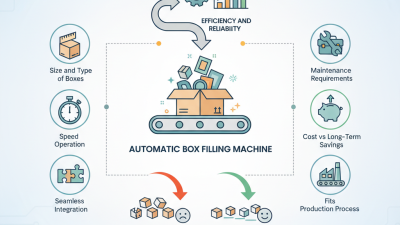

Choosing the right machine is crucial. Many users overlook the impact of machine size and speed on production capacity. A machine that is too small can cause delays. Too fast can compromise product quality. Proper evaluation of needs is essential to avoid costly mistakes. Many companies report issues with integration into existing production lines, highlighting the need for careful planning.

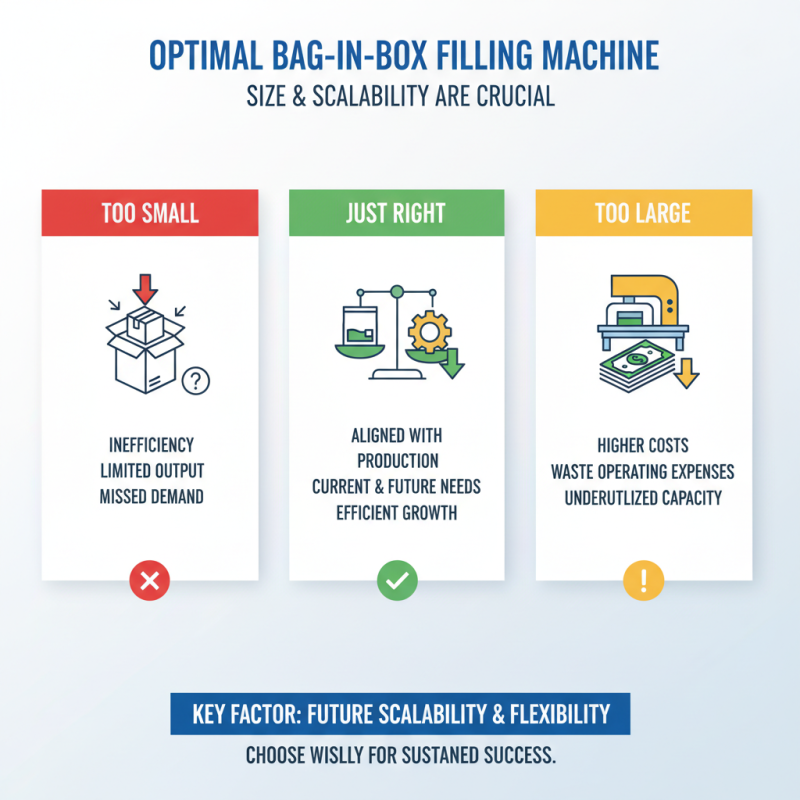

Key Factors in Selecting the Right Size for Your Filling Machine

Choosing the right bag in box filling machine is crucial. Size is a key factor in this decision. A machine that is too small may lead to inefficiencies. Conversely, an oversized machine can incur higher operational costs. According to a recent industry report, the optimal filling machine should align with production demands, not just current needs. Consider growth projections; flexibility in machine size can affect future scalability.

Analyzing your product’s characteristics is essential. For instance, liquid density and viscosity influence the necessary power and pump size. If a machine can't handle your product's specific properties, bottlenecks may occur. The report highlights that 40% of producers experienced production delays due to misalignment in machine size. Additionally, evaluate bag dimensions and fill capacity. A mismatch can lead to waste or excess downtime during changeovers. Aim for a filling machine that allows for quick adjustments without excessive reconfiguration time. This versatility is key to maintaining efficiency in a dynamic production environment.

Evaluating Filling Speed and Efficiency: Industry Benchmarks Explained

When selecting a bag in box filling machine, speed and efficiency are paramount. Industry benchmarks serve as a guiding light for evaluation. Typical machines exhibit a filling speed ranging between 200 to 600 bags per hour. However, the actual speed may vary based on several factors, including bag size and product viscosity.

It’s important to scrutinize not only the speed but also efficiency. Machines should maintain consistent filling accuracy, minimizing waste. A machine that fills quickly but inaccurately can lead to increased costs. Moreover, the downtime during operation is often overlooked. A machine that frequently requires maintenance can disrupt workflow significantly.

While industry standards provide a foundation, remember to consider your specific production needs. A high-speed machine isn't always the answer if it doesn't align with product requirements. Balancing speed, efficiency, and maintenance is key. Regular evaluations and adjustments may be necessary to optimize performance.

10 Essential Tips for Choosing a Bag in Box Filling Machine - Evaluating Filling Speed and Efficiency: Industry Benchmarks Explained

| Filling Machine Type | Filling Speed (Bags/Hour) | Efficiency Rate (%) | Error Rate (%) | Maintenance Frequency (Months) |

|---|---|---|---|---|

| Semi-Automatic | 300 | 85 | 5 | 6 |

| Fully Automatic | 600 | 92 | 2 | 12 |

| Rotary | 1000 | 95 | 1 | 18 |

| Piston | 400 | 88 | 4 | 9 |

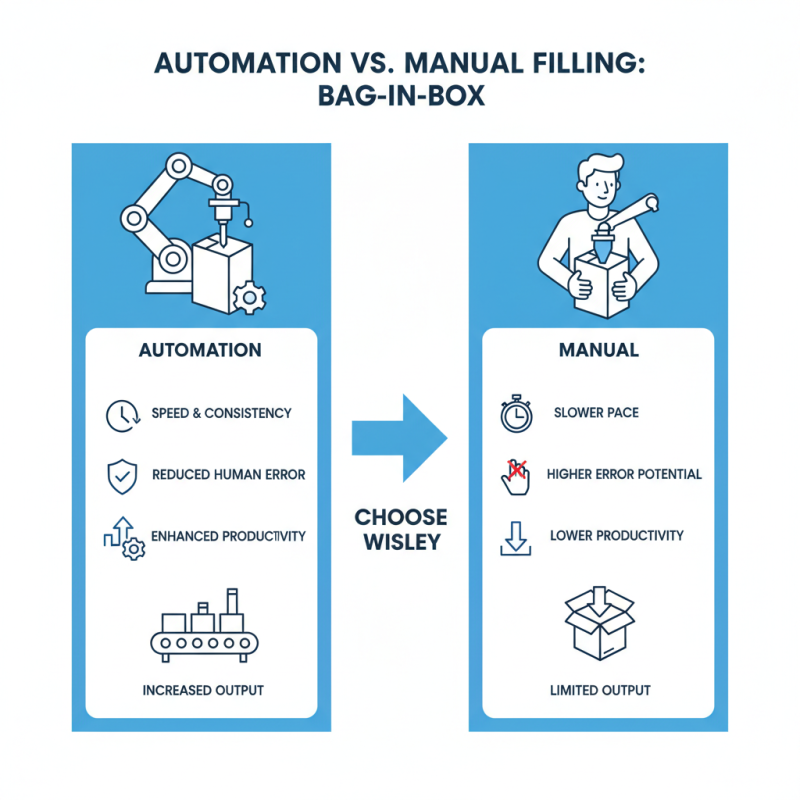

Importance of Automation vs Manual Operations in Filling Processes

Choosing between automation and manual operations in filling processes can be challenging. Automation offers speed and consistency. It reduces human error and enhances productivity. An automated bag in box filling machine can complete tasks quickly. This efficiency can lead to increased output.

However, manual operations still have their place. They allow for flexibility and adaptability in smaller production runs. Not every situation requires high-speed automation. Sometimes, manual filling is more practical, especially for unique products. Understanding your specific needs is essential. A blend of both methods might be necessary for optimal results.

It's also vital to assess the costs involved. Automated machines may require a larger initial investment. Maintenance can also be more complex over time. On the other hand, manual processes can be labor-intensive. Finding the right balance between automation and manual operations can be a journey. It's about continuous evaluation and adaptation. Each choice will bring benefits and challenges that must be navigated.

Maintenance and Support: Ensuring Long-Term Reliability of Your Machine

When investing in a bag in box filling machine, maintenance and support are crucial for long-term reliability. Regular maintenance can prevent unexpected failures. According to industry surveys, companies often face costly downtime due to inadequate maintenance practices. Implementing a routine service schedule can significantly extend the lifespan of your equipment.

Consider these tips: Ensure you understand the technical specifications of the machine. Training your staff on basic troubleshooting can reduce reliance on external support. It's vital to keep spare parts readily available. Delays in freight can impact production timelines dramatically. Inquire about the availability of service technicians in your area. Having local support can make a difference in response times.

Many manufacturers suggest that companies document maintenance activities. This practice helps track performance and identifies recurring issues. A proactive approach can save money. Yet, some businesses overlook this step, leading to more significant problems later on. According to reports, nearly 30% of machinery failures stem from neglecting routine upkeep. Prioritizing maintenance is not just about saving costs; it’s about ensuring your production remains uninterrupted.

Bag in Box Filling Machine Maintenance and Support

Related Posts

-

Why Choose a Pouch Up Bag for Your Travel Needs?

-

How to Choose the Right Automatic Box Filling Machine for Your Business?

-

2026 Best Juice Pasteurizer Machine for Quality Assurance?

-

2025 Top 10 Fruit Washers: Best Picks for Clean and Healthy Produce

-

What is Juice Processing Equipment and How Does it Work for Efficient Production

-

How to Choose the Best Bib Filler for Your Next Event in 2025