Top Fruit Processing Equipment Trends to Watch in 2025

As the fruit processing industry continues to evolve, understanding the emerging trends in fruit processing equipment is crucial for staying competitive in 2025. Experts in the field, such as Dr. Helen Thompson, a leading figure in food technology research, emphasize the importance of innovation: "The future of fruit processing equipment hinges on automation and sustainability—these will be the key drivers of efficiency and quality." This statement highlights the rising demand for advanced machinery that not only enhances productivity but also reduces the environmental impact of processing activities.

In light of these trends, manufacturers are increasingly focusing on integrating smart technologies and energy-efficient solutions into their equipment. As the industry prepares for a more sustainable future, it becomes essential for stakeholders to engage with these advancements and rethink traditional practices. With the growing consumer preference for fresh and minimally processed products, the evolution of fruit processing equipment must align with these demands to ensure market relevance in the years to come. As we explore the key trends to watch in 2025, it is clear that the landscape of fruit processing is set for a transformation that prioritizes both efficiency and sustainability.

Top Fruit Processing Equipment Trends to Watch in 2025

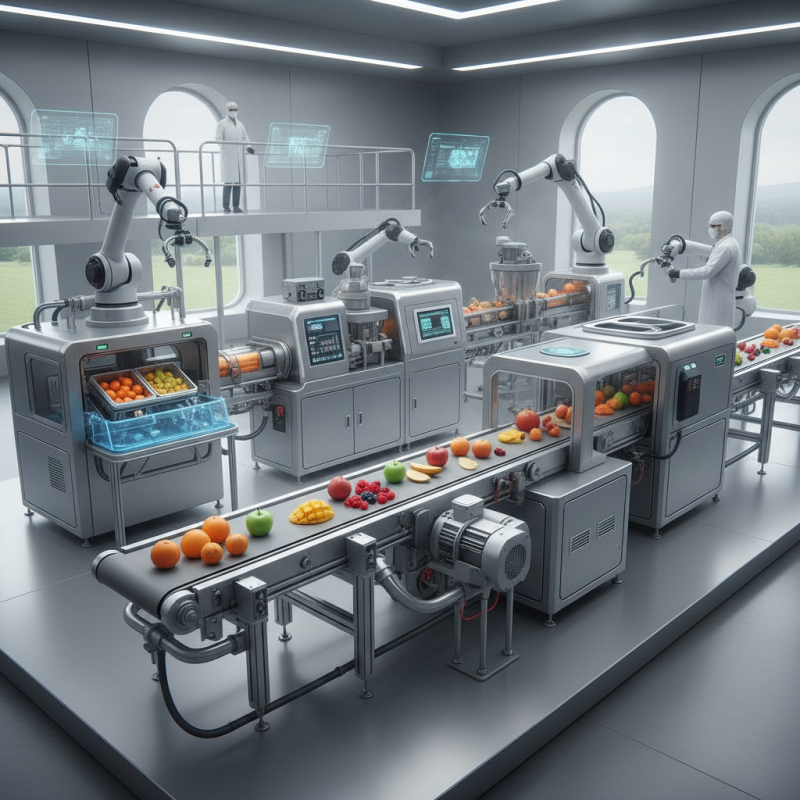

As we approach 2025, the fruit processing industry is set to witness transformative trends driven by advancements in technology and changing consumer preferences. One key trend is the increasing adoption of

automation and robotics in fruit processing facilities. Automated systems streamline various tasks such as sorting, washing, and packaging, leading to enhanced efficiency and reduced labor costs. This shift not only boosts productivity but also improves the quality and safety of processed fruits, catering to the growing demand for high-quality produce.

Another significant trend is the focus on sustainability and eco-friendly practices. As consumers become more environmentally conscious, fruit processing companies are exploring innovative ways to minimize waste and energy consumption. Implementing energy-efficient equipment and utilizing waste by-products for secondary applications are strategies gaining traction in the industry. Additionally, the use of biodegradable materials for packaging is on the rise, aligning with consumer preferences for sustainable products and bolstering brand reputation in a competitive market.

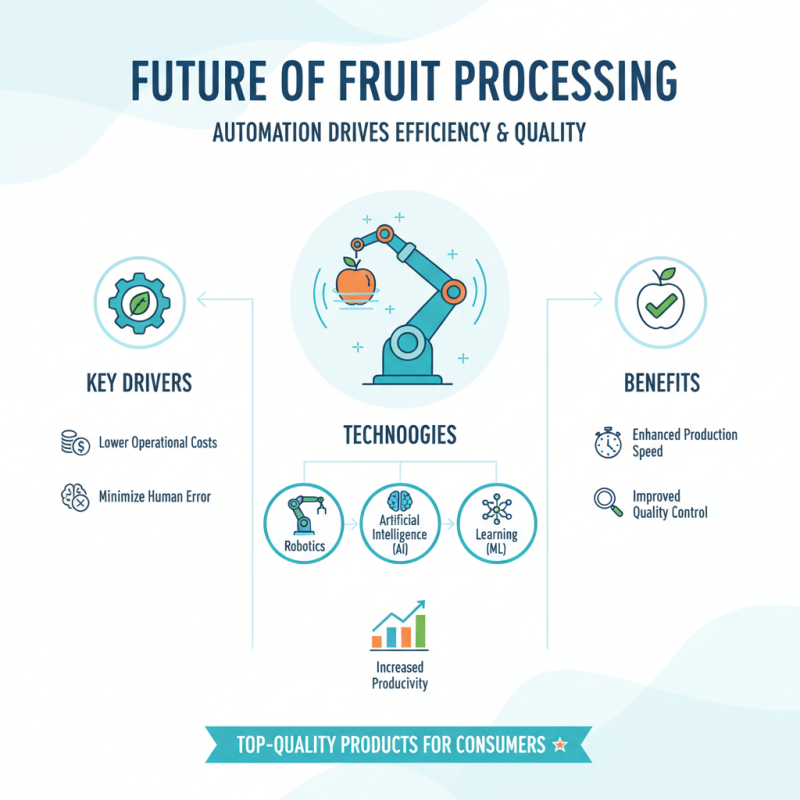

Increased Automation in Fruit Processing Facilities for Efficiency Gains

The fruit processing industry is witnessing a significant shift towards increased automation in facilities, driven by the need for greater efficiency and productivity. As companies seek to lower operational costs and minimize human error, the incorporation of advanced technologies like robotics, artificial intelligence, and machine learning is becoming more prevalent. Automated systems are not only enhancing the speed of production but also improving quality control, ensuring that consumers receive top-quality products consistently.

In 2025, we can expect to see even more sophisticated automated solutions integrated into fruit processing lines. These innovations will allow for real-time monitoring and adjustments throughout the processing stages, optimizing resource use and reducing waste. Furthermore, automation can facilitate a more flexible production environment, enabling facilities to quickly adapt to fluctuating market demands and production volumes. This level of adaptability is crucial, as the global market for processed fruits continues to evolve, driven by changing consumer preferences and health trends. Overall, the advancements in automation will play a pivotal role in shaping the future of the fruit processing sector, making operations more efficient and sustainable.

Emerging Technologies: AI and Machine Learning in Fruit Sorting Systems

The integration of artificial intelligence (AI) and machine learning into fruit sorting systems is revolutionizing the fruit processing industry. As producers seek to enhance efficiency and maintain product quality, these advanced technologies are being implemented to streamline operations. AI algorithms analyze various parameters such as size, color, and firmness to ensure only the highest quality fruits make it to the market. This not only minimizes waste but also maximizes profitability by delivering premium products to consumers.

Tips for adopting AI in fruit sorting include investing in high-quality sensors, which can significantly enhance the accuracy of sorting systems. Additionally, engaging with industry experts can help businesses tailor AI solutions to their specific needs, ensuring that the technology aligns well with existing processes. Continuous training of machine learning models is also essential, as it allows for adaptation to varying fruit characteristics and market demands over time.

Furthermore, companies should consider the scalability of their AI solutions. As the demand for processed fruits grows, having a flexible system that can adapt to increased production volumes while maintaining sorting accuracy will be crucial. By focusing on these aspects, fruit processors can effectively leverage AI and machine learning, setting themselves apart in a competitive market while meeting consumer expectations for quality and consistency.

Sustainability Trends: Energy-efficient Fruit Processing Machinery

As the fruit processing industry continues to evolve, sustainability has emerged as a pivotal theme shaping the design and implementation of machinery. In 2025, one of the foremost trends will be the shift towards energy-efficient fruit processing equipment. This development is primarily driven by the urgent need to reduce greenhouse gas emissions and lower energy costs. By investing in advanced technologies, processors can streamline their operations while minimizing their environmental footprint, contributing to a more sustainable future.

Energy-efficient machines utilize innovative systems such as variable frequency drives, advanced heating methods, and automation for optimal resource management. These advancements not only enhance production efficiency but also decrease waste and energy consumption. Furthermore, incorporating renewable energy sources, such as solar power, into processing facilities is gaining traction, allowing businesses to achieve higher levels of self-sufficiency and sustainability. As the industry adapts to these trends, the integration of energy-efficient machinery will play a crucial role in promoting sustainable practices and environmental stewardship in fruit processing.

Top Fruit Processing Equipment Trends to Watch in 2025

The Rise of Flexible and Modular Processing Equipment Solutions

The food processing industry is witnessing a significant transformation, with a notable shift towards flexible and modular processing equipment solutions. As consumer demand for diverse and customized products grows, manufacturers are exploring innovative equipment designs that offer adaptability. According to a recent report from Mordor Intelligence, the global food processing equipment market is projected to grow at a compound annual growth rate (CAGR) of 6.4% from 2020 to 2025. This trend emphasizes the need for equipment that can easily reconfigure to produce a variety of fruit products, thereby minimizing downtime and increasing operational efficiency.

Flexible processing systems not only accommodate different processing capabilities but also facilitate easier upgrades, allowing companies to remain competitive in a dynamic market. Research by Markets and Markets indicates that modular processing equipment can reduce operational costs by up to 20%, as these systems require less maintenance and can be scaled rapidly to meet changing production demands. This trend is particularly advantageous for small to medium-sized enterprises that seek to innovate without large capital investments.

Tips: When evaluating options for processing equipment, consider those that allow for easy integration with existing systems and provide ongoing support for modifications. Additionally, prioritize suppliers that offer comprehensive training and resources on equipment utilization, as this can enhance productivity and ensure smoother transitions during upgrades or changes in product lines. Embracing flexible and modular solutions will not only future-proof operations but also enhance the ability to respond swiftly to consumer trends.

Conclusion

The article "Top Fruit Processing Equipment Trends to Watch in 2025" highlights several key trends shaping the future of the fruit processing industry. Increased automation is driving efficiency gains in processing facilities, allowing for faster and more reliable operations. Additionally, emerging technologies such as artificial intelligence and machine learning are being integrated into fruit sorting systems, enhancing accuracy and reducing waste.

Sustainability trends are also prominent, with a focus on energy-efficient fruit processing equipment that minimizes environmental impact. Furthermore, there is a growing demand for flexible and modular processing equipment solutions, enabling facilities to adapt quickly to changing market needs. Finally, the integration of the Internet of Things (IoT) is revolutionizing fruit processing operations by enabling real-time monitoring and data analysis, further improving efficiency and productivity. Overall, these advancements are pivotal in shaping a more efficient and sustainable fruit processing landscape in the coming years.

Related Posts

-

Top Fruit Processing Equipment Trends to Watch in 2025

-

Revolutionizing the Way We Think About Fruit Processing Machinery for Sustainable Agriculture

-

2025 Top 10 Bag in Box Machines for Efficient Packaging Solutions

-

2025 How to Choose the Best Vegetable Processing Machine for Your Needs

-

2025 Top 10 Fruit Washers: Best Picks for Clean and Healthy Produce

-

Top 10 Automatic Bag Fillers for Efficient Packaging Solutions