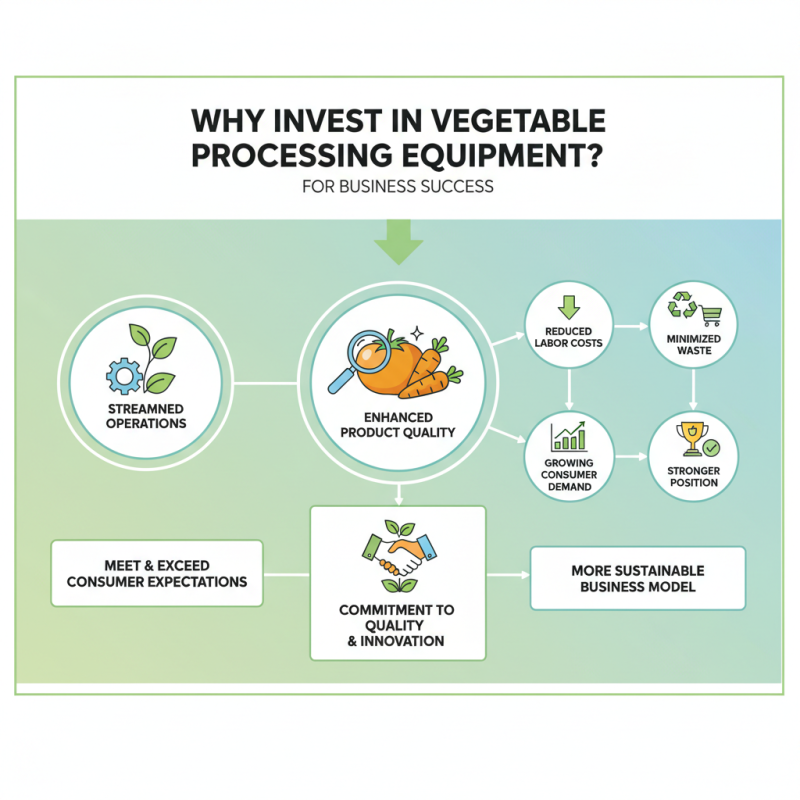

Why You Should Invest in Vegetable Processing Equipment for Your Business Success

In the competitive landscape of the food industry, investing in vegetable processing equipment is not just a smart move but a crucial strategy for ensuring long-term business success. According to industry expert Dr. Emily Williams, "The right vegetable processing equipment can dramatically enhance efficiency and product quality, ultimately leading to a stronger market position." With the growing consumer demand for fresh and processed vegetables, businesses that embrace modern processing technologies stand to benefit significantly.

The integration of state-of-the-art vegetable processing equipment streamlines operations, reduces labor costs, and minimizes waste, creating a more sustainable business model. As the market evolves, so too must processing methods; businesses that fail to adapt risk falling behind. By upgrading their equipment, companies can not only meet but exceed consumer expectations, ensuring they remain competitive in an ever-changing market landscape.

Ultimately, the investment in vegetable processing equipment represents a commitment to quality and innovation. In an industry where efficiency and product integrity are paramount, having the right tools can make all the difference in a company's growth and reputation. Embracing technology in vegetable processing is not merely an operational decision; it is a fundamental aspect of building a successful and resilient business.

Benefits of Investing in Vegetable Processing Equipment

Investing in vegetable processing equipment can significantly enhance your business's efficiency and profitability. One of the primary benefits is the increase in productivity that comes with modern machinery. Such equipment allows for faster processing times, enabling businesses to handle larger volumes of vegetables while maintaining quality. This efficiency not only meets the growing demand for processed vegetables but also helps to reduce labor costs, making it a sound financial decision for any operation.

Moreover, utilizing advanced vegetable processing equipment can improve product consistency and safety. With automated processes and technology designed to minimize human error, businesses can deliver a reliable product that meets regulatory standards. This not only builds consumer trust but also positions the business as a leader in quality assurance. Additionally, preserving the nutritional value and freshness of vegetables becomes easier, enhancing the overall appeal of the products in a competitive market. Investing in such equipment ultimately paves the way for innovation and growth in the vegetable processing sector.

Benefits of Investing in Vegetable Processing Equipment

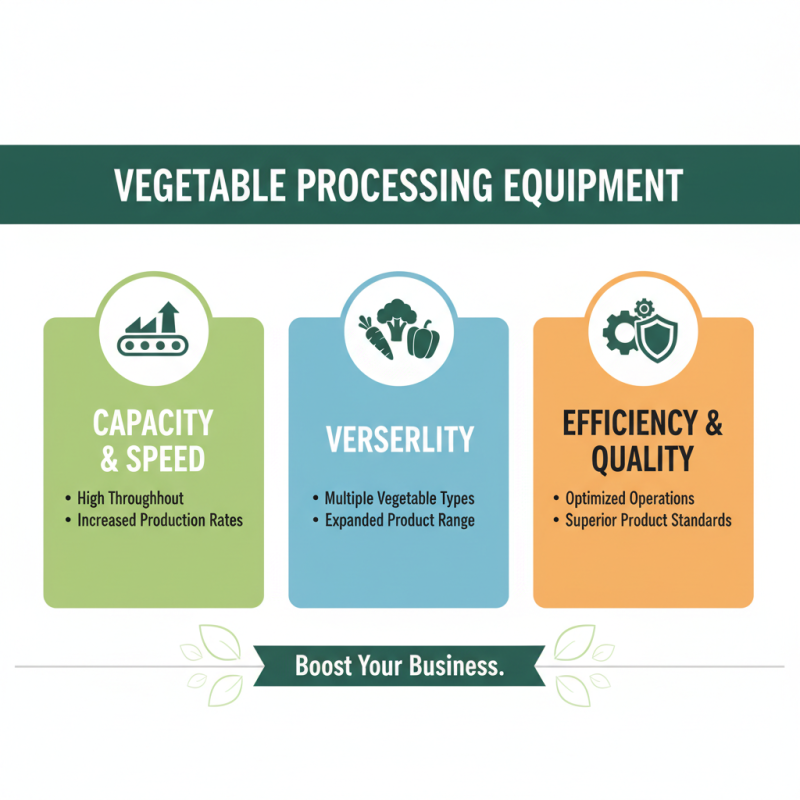

Key Features to Look for in Vegetable Processing Equipment

When investing in vegetable processing equipment, identifying the key features that can enhance your business's operational efficiency and product quality is essential. First and foremost, consider the machinery's capacity and processing speed. Equipment that can handle larger volumes while maintaining high throughput will facilitate greater production rates, leading to increased profitability. Additionally, look for machines that offer versatility in processing different types of vegetables, as this can enhance your product range and appeal to a wider customer base.

Another crucial feature is the ease of maintenance and operation. Equipment should be user-friendly, allowing your staff to operate it with minimal training. Furthermore, selecting machinery with accessible maintenance points can reduce downtime and ensure consistent operation. Incorporating automation features can also significantly enhance productivity by minimizing manual labor and improving precision in processing tasks.

**Tips:** Always assess the energy efficiency of the equipment; this can help reduce operational costs in the long term. Additionally, consider investing in equipment that offers advanced technology for monitoring and quality control, as ensuring the highest standards in food processing is crucial for consumer trust and safety. By focusing on these key features, you can make an informed decision that aligns with your business goals and supports sustainable growth.

Cost-Benefit Analysis of Vegetable Processing Equipment

The cost-benefit analysis of investing in vegetable processing equipment reveals significant advantages for businesses aiming to enhance their operational efficiency and profitability. According to a report by the Food Processing Association, processed vegetables can yield profit margins up to 40% higher than fresh produce, primarily due to extended shelf life and enhanced consumer convenience. This makes vegetable processing not only a strategic business move but also a necessity in meeting market demand for ready-to-eat and minimally processed foods.

On the initial investment front, while vegetable processing equipment may require a substantial capital infusion, the return on investment (ROI) can be remarkable. The USDA estimates that proper investment in processing equipment can reduce waste by up to 30%, maximizing the value derived from raw materials. Additionally, advances in technology and automation result in lower labor costs and increased production capabilities, further solidifying the financial case for such investments. The long-term benefits, including diversified product offerings and improved market competitiveness, underscore the critical role that vegetable processing equipment plays in driving business growth and sustainability.

Why You Should Invest in Vegetable Processing Equipment for Your Business Success - Cost-Benefit Analysis of Vegetable Processing Equipment

| Equipment Type | Initial Investment ($) | Annual Operating Cost ($) | Annual Revenue Increase ($) | Payback Period (Years) |

|---|---|---|---|---|

| Vegetable Washer | 10,000 | 2,000 | 8,000 | 1.25 |

| Peeling Machine | 15,000 | 3,500 | 12,000 | 1.25 |

| Cutting Machine | 20,000 | 4,000 | 15,000 | 1.33 |

| Blanching Equipment | 30,000 | 5,000 | 25,000 | 1.00 |

| Packaging Machine | 25,000 | 4,500 | 20,000 | 1.25 |

Types of Vegetable Processing Equipment for Different Applications

When it comes to vegetable processing, the variety of equipment available can be overwhelming. Different applications require specific tools to ensure efficiency and quality. For instance, if your business focuses on cleaning and sorting vegetables, equipment like wash tanks and vibrating conveyers are essential. These machines help maintain the freshness and quality of your products while saving valuable labor time.

For those aiming to process vegetables into ready-to-eat meals or packaged goods, cutting machines and blanchers are vital. These tools can drastically cut down processing time and enhance product consistency. Additionally, if you are involved in preserving vegetables, dehydrators and vacuum packaging machines become crucial. They ensure that you maintain the nutritional value and extend the shelf life of your products.

**Tips:** When selecting vegetable processing equipment, consider the scale of your operation and the types of vegetables you'll be working with. It’s important to choose versatile machines that can handle various tasks, as this will increase your production efficiency. Don’t forget to factor in maintenance costs and available support, as reliable service is critical for minimizing downtime.

Impact of Vegetable Processing on Business Growth and Sustainability

The impact of vegetable processing on business growth and sustainability cannot be overstated. As consumer demand for fresh, convenient, and healthy food options continues to rise, businesses that invest in vegetable processing equipment position themselves to meet this demand while enhancing operational efficiency. According to a report by Research and Markets, the global vegetable processing market is projected to grow at a CAGR of 6.5% over the next five years, underlining the increasing importance of this sector for long-term business success. Integrating advanced processing techniques not only boosts product quality but also extends shelf life, thereby reducing food waste—an essential factor in promoting sustainability.

Investing in vegetable processing equipment can significantly yield cost savings and streamline production. For instance, implementing automated slicing and dicing machines can reduce labor costs and improve consistency in product quality. Additionally, according to the Food Processing Industry Association, businesses that adopt sustainable practices can reduce operational costs by up to 30%. This highlights the dual benefit of such investments, as they not only drive profitability but also contribute to an eco-friendly brand image.

Tip: Explore local subsidies or grants that support sustainable practices in food processing. Many governments offer financial incentives for businesses that adopt environmentally friendly technologies.

Tip: Regularly assess your production process to identify bottlenecks and areas for improvement. Investing in state-of-the-art equipment can help enhance overall efficiency and product output.

Related Posts

-

2025 How to Choose the Best Vegetable Processing Machine for Your Needs

-

Exploring the Versatility of Bib Bag in Box for Eco Friendly Packaging Solutions

-

2025's Top Vegetable Washers: Best Features and Buying Guide

-

Top Fruit Processing Equipment Trends to Watch in 2025

-

10 Best Bib Fillers to Enhance Your Bike's Performance in 2023

-

Top 10 Bag in Box Filling Equipment Options for Your Business Success