What is Juice Processing Equipment and How Does it Work for Efficient Production

Juice processing equipment plays a vital role in the fruit juice industry, streamlining the production process and enhancing efficiency. According to industry expert Dr. Emily Chen, a renowned food processing engineer, "The right juice processing equipment not only maximizes yield but also preserves the nutritional integrity of the juice." This statement encapsulates the essence of modern juice production, where technology and innovation intersect to meet consumer demands for high-quality beverages.

As the global market for juice continues to expand, understanding the operational mechanics of juice processing equipment becomes increasingly important. From extraction machinery to pasteurization systems, each component is designed to optimize various stages of juice production, ensuring a product that is both delicious and safe for consumption. With advances in technology, manufacturers can now achieve higher efficiency rates while minimizing waste and maintaining the natural flavors and nutrients inherent in fresh fruits.

In an era where health-conscious consumers are driving demand for fresh, nutrient-rich products, investing in state-of-the-art juice processing equipment is no longer a luxury but a necessity. As the industry evolves, so too does the equipment that supports it, paving the way for a future where quality and efficiency are paramount in juice production.

What is Juice Processing Equipment?

Juice processing equipment refers to the various machines and technology utilized in the extraction, processing, and packaging of juice from fruits and vegetables. This equipment is essential for ensuring that the juice produced is of high quality, safe for consumption, and efficient in production. The process typically includes several stages such as washing, cutting, mashing, pressing, and pasteurization. According to a report from the Food and Agriculture Organization (FAO), the global juice market is projected to reach approximately $170 billion by 2026, highlighting the demand for efficient processing technologies that can keep up with this growth.

Key components of juice processing equipment include fruit washers, crushers, juice extractors, and pasteurizers. Each of these plays a vital role in enhancing the quality and shelf life of juice. For instance, the use of hydraulic or mechanical presses ensures maximum juice yield while minimizing pulp and waste. The effectiveness of processing equipment not only influences the quality of the final product but also impacts operational efficiency. Reports indicate that investing in advanced juice processing technologies can reduce production costs by up to 30%, allowing businesses to enhance profitability while meeting increasing consumer demand for fresh and natural beverage options.

Types of Juice Processing Equipment Available

Juice processing equipment is essential for the production of high-quality juice, involving technologies that enhance extraction, filtration, and pasteurization. The primary types of equipment include juice extractors, pasteurizers, and packaging machines, each serving a vital role in the juice production line. According to a recent industry report by Grand View Research, the global fruit juice processing market was valued at approximately $31 billion in 2021 and is expected to grow significantly, prompting manufacturers to invest in advanced processing technologies that increase efficiency and product quality.

Juice extractors can vary from traditional cold-press devices to high-capacity industrial machines, each designed for specific types of fruits and operational scales. Cold-press juicers are noted for their ability to preserve more nutrients and enzymes, while centrifugal juicers are efficient for large-scale production. Additionally, pasteurization equipment plays a crucial role in extending shelf life by eliminating harmful microorganisms. The global juice pasteurization equipment market was anticipated to grow at a CAGR of 5.6% from 2022 to 2028, as processors seek to meet both safety standards and consumer demands for fresh products.

Furthermore, advancements in packaging technology are vital to maintaining juice quality during storage and distribution. Vacuum-sealing machines and modified atmosphere packaging are increasingly employed to minimize oxidation and extend the freshness of juices. Industry analysts project that the demand for innovative packaging solutions will continue to rise, driven by consumer preferences for convenience and sustainability. Hence, investing in modern juice processing equipment is fundamental for manufacturers aiming to enhance production efficiency and meet growing market demands.

What is Juice Processing Equipment and How Does it Work for Efficient Production

| Type of Equipment | Function | Key Features | Efficiency Rate |

|---|---|---|---|

| Juice Extractor | Extracts juice from fruits/vegetables | High extraction efficiency, adjustable settings | 85-95% |

| Pasteurizer | Heats juice to eliminate pathogens | Rapid heating, energy-efficient | 99.9% pathogen reduction |

| Filtration System | Removes solid particles and impurities | Membrane or strainer filtration | Up to 99% solids removal |

| Filling Machine | Fills bottles or containers with juice | Automated filling, adjustable volumes | Up to 120 bottles/hour |

How Juice Processing Equipment Works

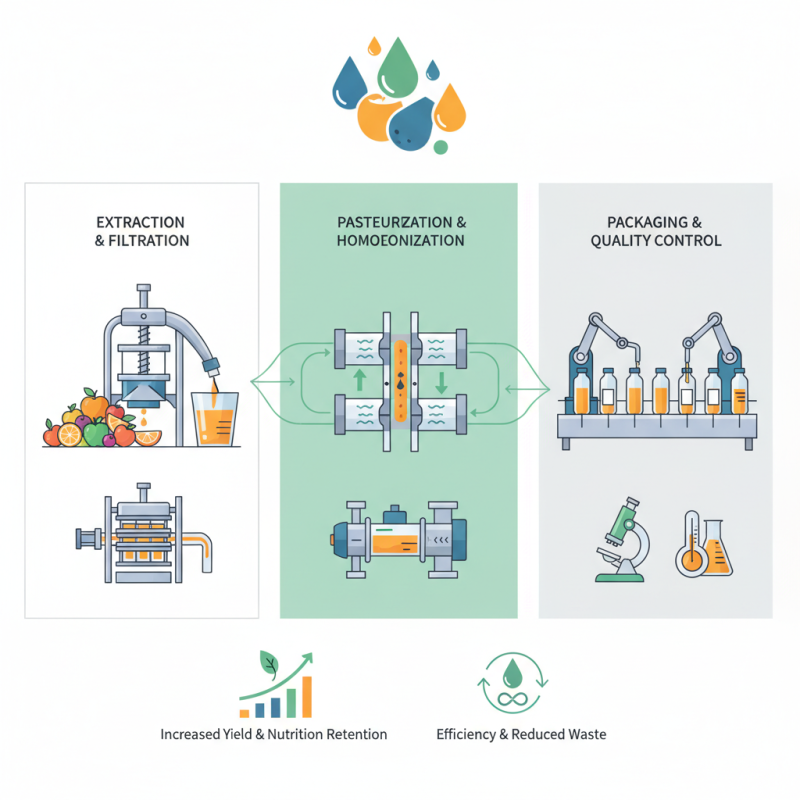

Juice processing equipment plays a vital role in transforming fresh fruits and vegetables into flavorful juices. The process begins with the selection and preparation of raw materials, where fruits are washed, sorted, and inspected for quality. This initial stage ensures that only the best produce is used, which is crucial for maintaining the taste and nutritional value of the juice. Following this, the fruits undergo crushing or milling to break down their cellular structure, allowing for maximum juice extraction.

Once the raw materials are processed, extraction methods, such as hydraulic pressing or centrifugal juicing, are employed. These methods efficiently separate the juice from the pulp and other solid components. The extracted juice is then subject to clarification, where enzymes or filtration techniques are used to remove any remaining solids, resulting in a smooth and clear product. To enhance shelf life and safety, pasteurization is often applied, heat-treating the juice to eliminate harmful microorganisms while preserving its essential nutrients.

Throughout this process, modern juice processing equipment is designed for optimal efficiency and automation, reducing labor costs and minimizing waste. By incorporating advanced technologies, such as automated filling and packaging systems, manufacturers can streamline production and ensure consistent quality in their juice offerings. This integration of technology not only speeds up the production cycle but also helps maintain the freshness and flavor profile that consumers expect from high-quality juices.

Juice Production Efficiency by Equipment Type

Key Features of Efficient Juice Processing Equipment

Efficient juice processing equipment is essential for optimizing production while maintaining the quality and nutritional value of juices. Key features of such equipment include advanced extraction technology, which allows for maximum juice yield and minimal waste. This technology often involves methods like cold pressing or centrifugal extraction, which preserve the natural flavors and nutrients of the fruits and vegetables being processed. Moreover, temperature control during extraction is crucial, as it helps prevent the degradation of sensitive vitamins and enzymes, ensuring a high-quality end product.

Another important feature of efficient juice processing equipment is automation and ease of operation. Automated systems streamline the processes from washing and cutting to extracting and bottling, significantly reducing labor costs and human error. User-friendly interfaces and adjustable settings enable operators to tailor the production process to specific juice types, enhancing flexibility and efficiency. Additionally, the inclusion of hygienic materials and design ensures that the equipment meets safety standards, facilitating easier cleaning and maintenance, which are vital for consistent production and compliance with food safety regulations.

Benefits of Modern Juice Processing Technology

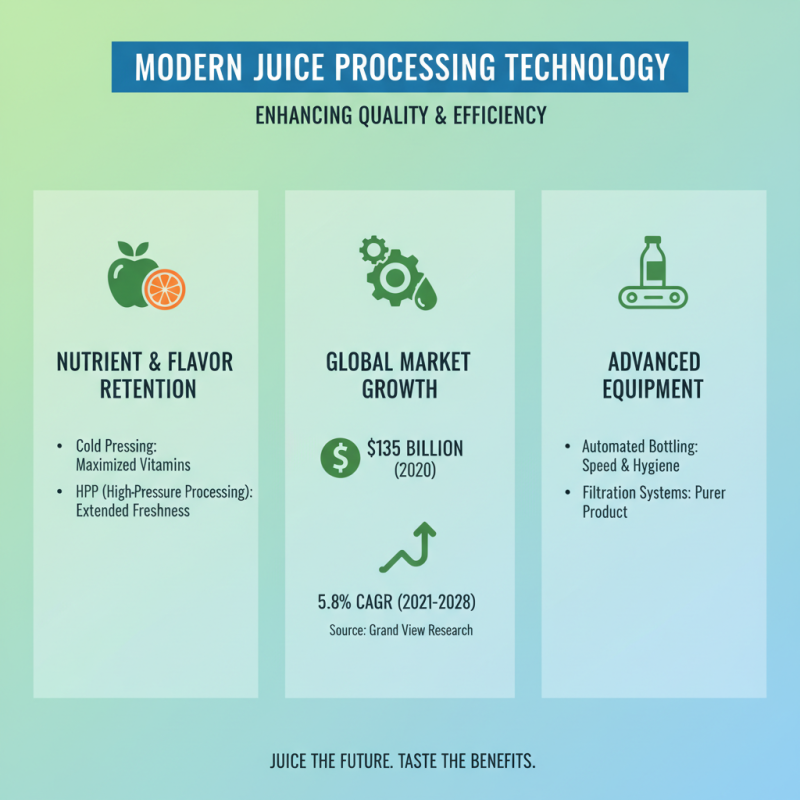

Modern juice processing technology offers numerous benefits that enhance both the efficiency and quality of juice production. According to a report by Grand View Research, the global fruit juice market was valued at approximately $135 billion in 2020 and is expected to grow at a compound annual growth rate (CAGR) of 5.8% from 2021 to 2028. This growth is largely driven by advancements in processing equipment that allow manufacturers to produce juice that retains more nutrients and flavor. Technologies such as cold pressing, high-pressure processing (HPP), and automated bottling systems have revolutionized how juice is extracted and packaged, resulting in products that not only taste better but also boast higher vitamin and mineral content.

The environmental benefits of modern juice processing technology are also significant. Efficient processing equipment minimizes waste and optimizes resource use. For instance, advanced extraction systems can increase juice yield from fruits by up to 30%, allowing producers to maximize their raw material without compromising quality. Additionally, automation reduces labor costs and the likelihood of human error, leading to a more consistent product. According to the Food and Agriculture Organization (FAO), the implementation of such technologies can contribute to reducing the carbon footprint of juice production by as much as 20%, aligning with global sustainability goals. These advancements not only cater to the growing consumer demand for healthier options but also support producers in their initiatives toward more sustainable practices.

Related Posts

-

Why Choosing the Right Juice Processing Equipment Is Essential for Your Business

-

Top 10 Bag in Box Holders to Enhance Your Beverage Experience in 2023

-

2025 Top 10 Bag in Box Machines for Efficient Packaging Solutions

-

Top Fruit Processing Equipment Trends to Watch in 2025

-

How to Choose the Best Juice Pasteurizer Machine for Your Business Needs

-

2025 How to Choose the Best Vegetable Processing Machine for Your Needs