What is a Liquid Bag Filler and How Does it Work?

A liquid bag filler is an essential machine in various industries. It streamlines the packaging process for liquids, ensuring efficiency and consistency. This equipment is widely used in food, beverage, and pharmaceutical sectors. With its increasing importance, many new users find it challenging to understand its workings.

The core function of a liquid bag filler involves automatically filling bags with precise amounts of liquid. It minimizes waste and enhances production speed. Different bag fillers cater to various types of liquids, from thick sauces to thin oils. Users must consider factors like viscosity and container size to choose the right machine.

While liquid bag fillers significantly improve operations, they also pose challenges. Maintenance can be tricky, and staff training is often needed. Balancing speed and accuracy requires constant monitoring. Understanding these nuances can help manufacturers make informed decisions about their packaging needs.

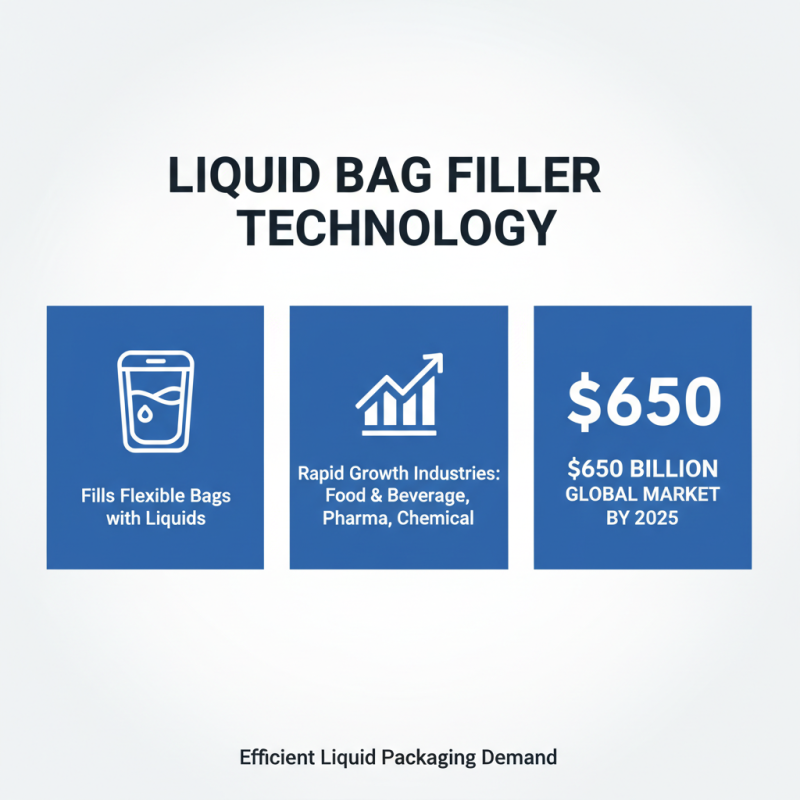

Definition of a Liquid Bag Filler

A liquid bag filler is a machine designed to fill flexible bags with liquid products. This technology has grown rapidly in industries such as food and beverage, pharmaceuticals, and chemical manufacturing. According to industry reports, the global liquid packaging market is projected to reach $650 billion by 2025. This growth emphasizes the demand for efficient liquid filling solutions.

Liquid bag fillers operate by drawing liquid from a reservoir and precisely dispensing it into pre-made bags. The process often involves various techniques, including gravity, pressure, and vacuum filling. Research indicates that automated liquid bag fillers can increase production efficiency by up to 30%. However, the complexity of these systems can lead to maintenance challenges.

Many companies face issues in achieving consistent fill levels. Variations can occur due to changes in liquid viscosity or bag material. Such discrepancies may result in waste and increased costs. Additionally, handling sensitive liquids requires careful calibration. This lack of standardization is an area that often requires further evaluation in striving for optimal performance. The need for ongoing training and quality checks becomes apparent in managing these systems effectively.

Components of a Liquid Bag Filler

Liquid bag fillers are essential for various industries. They are designed to fill bags with liquids efficiently. Understanding their components helps us grasp their functionality.

A liquid bag filler typically includes a filling machine, nozzles, and a control system. The filling machine regulates the flow of liquid. It ensures precise measurements. Nozzles are crucial. They direct the liquid into the bag. Some nozzles even minimize spillage, optimizing the process. The control system monitors settings and adapts as needed.

However, not all fillers are perfect. Some models struggle with different liquid viscosities. This inconsistency can lead to overflow or underfilling. Operators may need extra training to handle various liquids. Each component must be regularly maintained to ensure peak performance. Small issues can disrupt the entire filling process. Continuous improvement can help overcome these challenges.

Liquid Bag Filler Performance Metrics

How Liquid Bag Fillers Operate

Liquid bag fillers are essential in packaging industries. They help automate the filling of bags with liquids. These machines can handle various fluids, from water to sauces. Understanding how they operate can enhance efficiency in production.

Liquid bag fillers typically use a pump system. This system draws liquid from a storage tank. Then, it dispenses the liquid into bags. The process often involves sensors to monitor fill levels. It ensures precision and reduces waste. Various features can be added for better control. For example, adjustable speed settings help accommodate different flow rates.

Tips: Regular maintenance is key to keeping fillers running smoothly. Inspect hoses and seals frequently to prevent leaks. It's crucial to train staff properly on machine operation. Even minor mistakes can lead to spills and losses. Adapting the system to your needs might take time. Experimenting with different settings can yield better results.

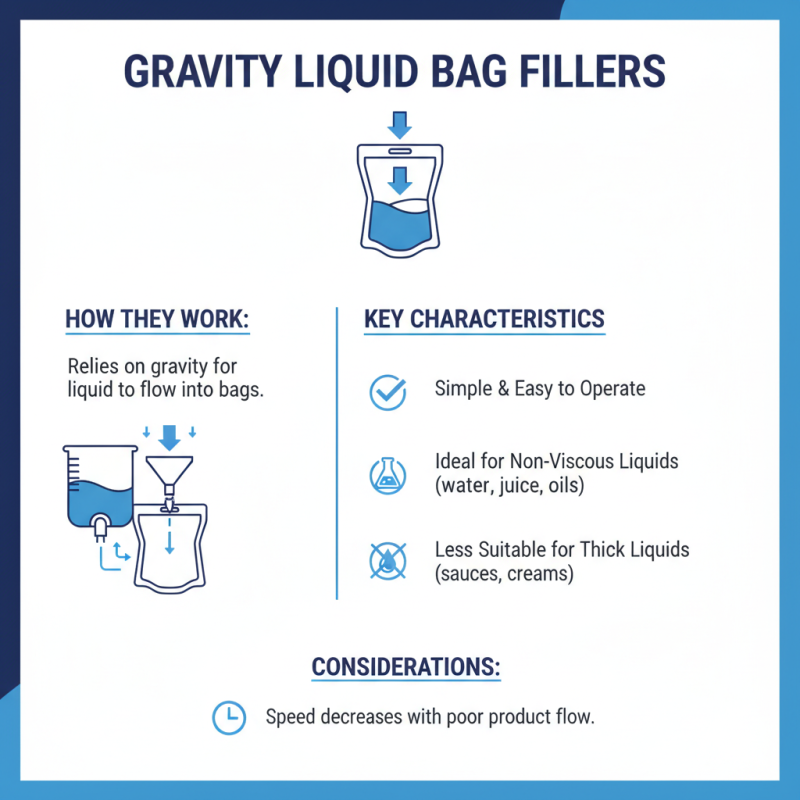

Types of Liquid Bag Fillers

When exploring the types of liquid bag fillers, a few options stand out. Gravity fillers are simple devices that rely on gravity for the filling process. They are easy to operate, and often used for non-viscous liquids. However, they might not be the best choice for thicker substances. Their speed can decrease if the product does not flow well.

Another common type is the pump filler. These machines use a pump to transfer liquid into bags. They handle various viscosities effectively. However, it’s crucial to choose the right pump type. Not every pump is suitable for all liquids. A mismatch might lead to issues such as leaks or spills.

Lastly, there are volumetric fillers. These fillers measure an exact amount of liquid per cycle. They are ideal for precision. Yet, they can struggle with foamy liquids. It's important to consider the limitations of each system. Each type of liquid bag filler has unique advantages and disadvantages. It’s essential to evaluate specific needs before choosing one.

Applications and Industries Utilizing Liquid Bag Fillers

Liquid bag fillers are essential in many industries. They help fill bags with liquids like chemicals, food, and beverages. The systems efficiently manage the process, ensuring precision and speed. These machines often handle various viscosity levels and container sizes. Operators appreciate how they can streamline production lines.

Food and beverage industries benefit significantly from liquid bag fillers. They improve the packaging of sauces, oils, and juices. In chemical manufacturing, fillers are vital for safely packaging hazardous liquids. The pharmaceutical sector also relies on these machines. They ensure sterile conditions while filling vials or bags with medicines.

When using liquid bag fillers, consider regular maintenance. It can help prevent costly downtime. Always train staff properly. This reduces errors and improves overall safety. Be mindful of the machine’s limits. Overloading can lead to imbalances and malfunction.Each industry can leverage this technology, but careful attention makes a difference.

What is a Liquid Bag Filler and How Does it Work? - Applications and Industries Utilizing Liquid Bag Fillers

| Application | Industry | Filler Type | Common Liquids | Benefits |

|---|---|---|---|---|

| Food & Beverage Packaging | Food Industry | Gravity Filler | Juices, Sauces | High efficiency, gentle handling |

| Chemical Filling | Chemical Industry | Piston Filler | Detergents, Cleaning agents | Accurate dosing, reduced waste |

| Pharmaceuticals | Pharmaceutical Industry | Volumetric Filler | Syrups, Solutions | Precision, compliance with regulations |

| Cosmetic Products | Cosmetics Industry | Time Pressure Filler | Lotions, Oils | High speed, versatile |

| Liquid Fertilizers | Agriculture | Pump Filler | Nutrient Solutions | Consistency, scalability |

Related Posts

-

Innovative Uses for Bag in Box Filling Machines in Beverage Production

-

What is a Pouch Filler and How Does it Work?

-

What is a Liquid Bag Filler and How Does It Work?

-

What is an Automatic Bag Filler and How Does It Work?

-

2026 Best Juice Pasteurizer Machine for Quality Assurance?

-

Top 10 Benefits of Using Bag in Box Pouch for Packaging and Storage?