2025 Top 10 Bag in Box Machines for Efficient Packaging Solutions

As the demand for efficient and sustainable packaging solutions continues to rise, the “bag in box machine” has emerged as a pivotal technology within the packaging industry. According to a recent report by Smithers Pira, the global bag-in-box packaging market is projected to grow at a compound annual growth rate (CAGR) of 4.3% from 2021 to 2026, reaching a market value of USD 4.12 billion. This significant growth underscores the increasing reliance on bag in box machines to meet the evolving needs of various sectors, including food and beverage, chemicals, and personal care products.

Industry expert Dr. Emily Johnson, a notable figure in packaging technology, emphasizes the critical role of bag in box machines in enhancing packaging efficiency. She states, “The integration of advanced technology in bag in box machines not only optimizes operational workflows but also contributes to sustainability initiatives through reduced waste and improved recyclability.” This perspective highlights the transformative impact of these machines as manufacturers seek to innovate while adhering to environmental standards.

With the upcoming 2025 projection in mind, exploring the top 10 bag in box machines available in the market becomes essential for businesses seeking to enhance their packaging capabilities. This analysis aims to identify the leading models that exemplify durability, efficiency, and sustainability, positioning companies for success in a competitive landscape.

Innovative Features of the 2025 Top Bag in Box Machines

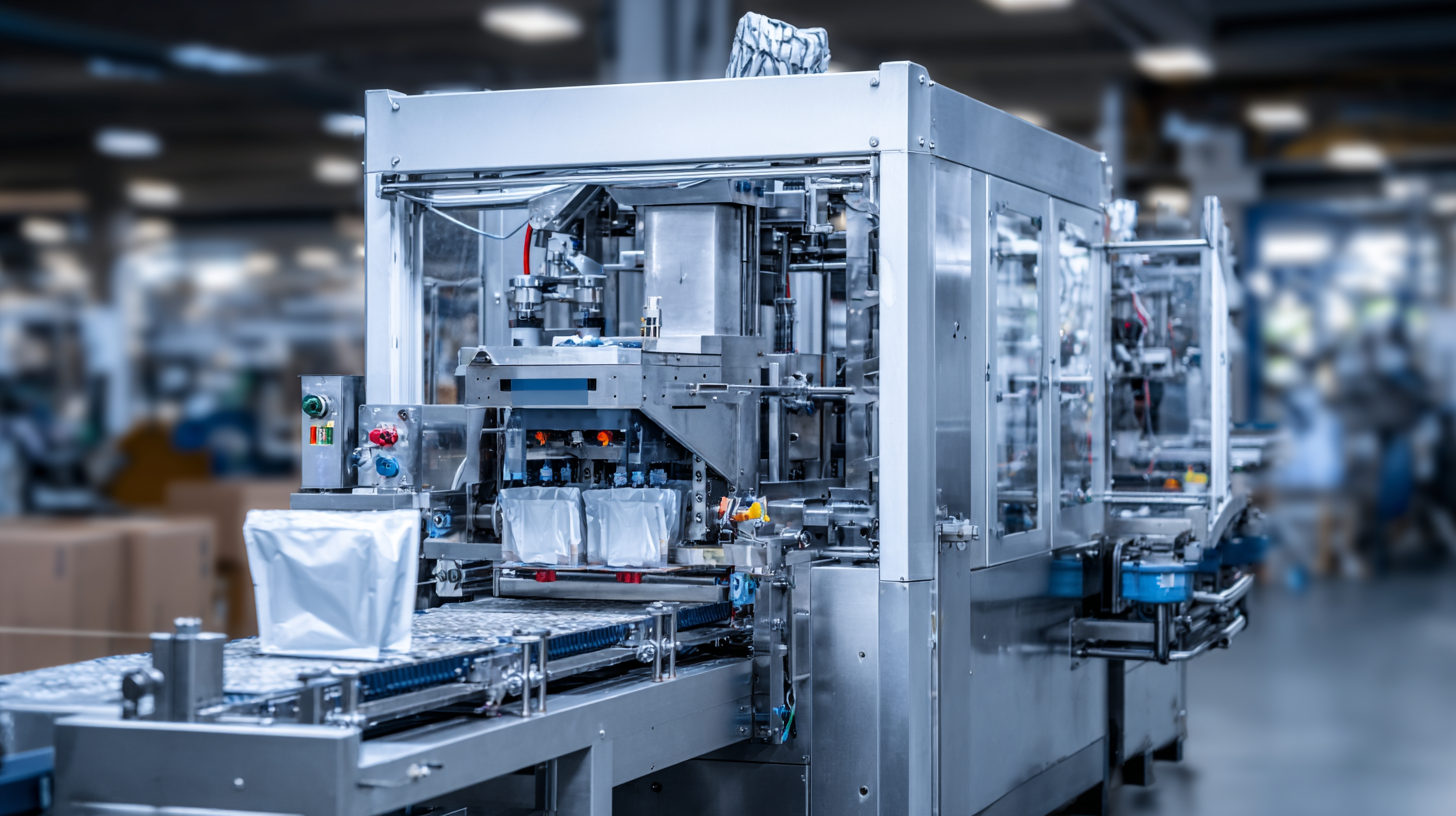

The 2025 Top Bag in Box machines are revolutionizing packaging solutions with their innovative features designed to enhance efficiency and productivity. One of the standout advancements is the integration of automation technology, which minimizes manual intervention and significantly reduces the risk of human error. These automated systems can handle various bag sizes and materials seamlessly, allowing for quick product changes and adaptation to diverse packaging requirements. Moreover, they include real-time monitoring systems that provide data analytics, ensuring consistent quality control throughout the packaging process.

Another impressive feature is the eco-friendly design incorporated into many of these machines. Manufacturers are prioritizing sustainability by utilizing recyclable materials and energy-efficient components, significantly lowering the environmental impact of packaging operations. Additionally, many models now come equipped with advanced sealing mechanisms that not only enhance product preservation but also reduce waste. Through the implementation of these innovative features, the 2025 Top Bag in Box machines are setting new standards for efficiency, sustainability, and reliability in the packaging industry.

Comparative Analysis of Efficiency and Productivity Metrics

In the realm of packaging technology, the Bag in Box (BiB) system has emerged as a leading solution for efficient and productive packaging. A comparative analysis of the top 10 Bag in Box machines reveals significant variations in their efficiency and productivity metrics. When assessing these machines, factors such as speed, versatility, and waste minimization are crucial indicators of performance. For instance, some machines boast the capability to package various liquid types—ranging from sauces to beverages—without extensive downtime, thus enhancing overall operational throughput.

Moreover, energy consumption and ease of maintenance play pivotal roles in determining the long-term viability of these machines. In the comparative study, specific models outperform others by utilizing advanced technology that reduces energy requirements while still maximizing output. Furthermore, machines designed for ease of cleaning and quick changeovers contribute significantly to minimizing production halts, allowing manufacturers to maintain a consistent operational flow.

As industries increasingly seek to optimize their packaging processes, the insights gained from analyzing these efficiency and productivity metrics will be vital for making informed investment decisions regarding Bag in Box machinery.

Cost-Effectiveness: A Review of Top Bag in Box Machines

In the competitive world of packaging solutions, bag in box (BiB) machines stand out for their cost-effectiveness and efficiency. According to a report from MarketsandMarkets, the global bag in box packaging market is projected to reach USD 4.67 billion by 2025, with a CAGR of 5.2% between 2020 and 2025. This growth reflects the increasing demand for sustainable packaging solutions, as BiB not only reduces packaging waste but also minimizes transportation costs due to their lightweight design.

Key features contributing to the cost-effectiveness of top BiB machines include automation and versatility. Machines that offer automated filling and sealing can significantly reduce labor costs and operational downtime, a finding highlighted in a 2023 Smithers Pira report, which notes that automation can lead to a 20% reduction in total operating costs. Additionally, the ability to handle various sizes and types of bags makes these machines adaptable for diverse products, ranging from liquids to dry foods, allowing manufacturers to optimize production lines without extensive investment in multiple systems.

2025 Top 10 Bag in Box Machines - Cost-Effectiveness Comparison

This chart illustrates the cost-effectiveness scores of the top 10 Bag in Box machines in 2025. Each machine's score is based on efficiency, productivity, and overall cost efficiency for packaging solutions.

Sustainability Considerations in Bag in Box Packaging Solutions

Sustainability has become a crucial consideration in the design and implementation of Bag in Box (BiB) packaging solutions. As companies strive to reduce their carbon footprints and minimize waste, innovations in BiB technology are increasingly focusing on eco-friendly materials and efficient production processes. Many manufacturers are now utilizing recycled and biodegradable materials in their packaging, which not only appeals to environmentally conscious consumers but also aligns with global sustainability goals.

Additionally, the efficient use of resources in BiB machines contributes significantly to reducing environmental impacts. Advanced technologies allow for precise filling and sealing, minimizing the amount of packaging material needed while ensuring product integrity. Moreover, these machines are often designed to optimize energy consumption, further decreasing their environmental footprint. By integrating sustainability into the packaging process, businesses can enhance their brand reputation and foster consumer trust, paving the way for a greener future in the packaging industry.

User-Friendly Technologies in Modern Bag in Box Machinery

The modern Bag in Box (BiB) machinery landscape is evolving rapidly, driven by a demand for user-friendly technologies that enhance efficiency and streamline operations. According to a report from Smithers Pira, the global market for Bag in Box packaging has experienced significant growth, projected to reach $3.6 billion by 2025. This demand is fueled by the need for more sustainable packaging solutions that minimize waste while providing an effective means of preserving products.

User-friendly technologies in BiB machinery are central to this transformation. Innovations such as touch-screen interfaces, automated filling systems, and advanced monitoring controls are now commonplace, allowing operators to manage processes with ease and precision. A survey by Packaging Strategies found that 68% of companies prioritize ease of use in machinery, as it directly correlates with reduced training time and increased productivity. Integration of IoT features into BiB machines also enables real-time tracking and analytics, providing manufacturers with valuable insights to optimize their packaging operations further and respond swiftly to market demands.

As consumer preferences shift towards more convenient and sustainable packaging options, the emphasis on user-friendly technologies will likely shape the future of the Bag in Box industry, driving manufacturers to adopt solutions that not only meet the needs of today but also anticipate the requirements of tomorrow.

2025 Top 10 Bag in Box Machines for Efficient Packaging Solutions

| Machine Model | Production Capacity (Liters/Hour) | Power Consumption (kW) | Bag Size Compatibility | Features |

|---|---|---|---|---|

| Model A | 1000 | 5.0 | 1-5 liters | Automatic filling, Quick changeover |

| Model B | 800 | 4.5 | 2-10 liters | Easy maintenance, Compact design |

| Model C | 1200 | 6.5 | 1-20 liters | User-friendly interface, Integrated conveyor |

| Model D | 600 | 3.0 | 1-5 liters | High accuracy, Low noise operation |

| Model E | 1500 | 7.0 | 5-15 liters | Energy-efficient, Advanced safety features |

| Model F | 900 | 5.5 | 3-10 liters | Scalable, Multi-format capable |

| Model G | 700 | 4.0 | 2-8 liters | Robust construction, Fast setup |

| Model H | 1100 | 6.2 | 5-20 liters | Automated cleaning, User-friendly |

| Model I | 950 | 5.3 | 1-12 liters | Flexible configurations, Minimal downtime |

| Model J | 1300 | 7.5 | 10-30 liters | High-speed operation, Smart controls |