Monoblock system offers 5, 8, and 12 filling heads and provides a compact and efficient solution, ensuring a smooth and hygienic transition from bottle infeed to a perfectly sealed finished product.

Capacity – 500-2,500 BPH.

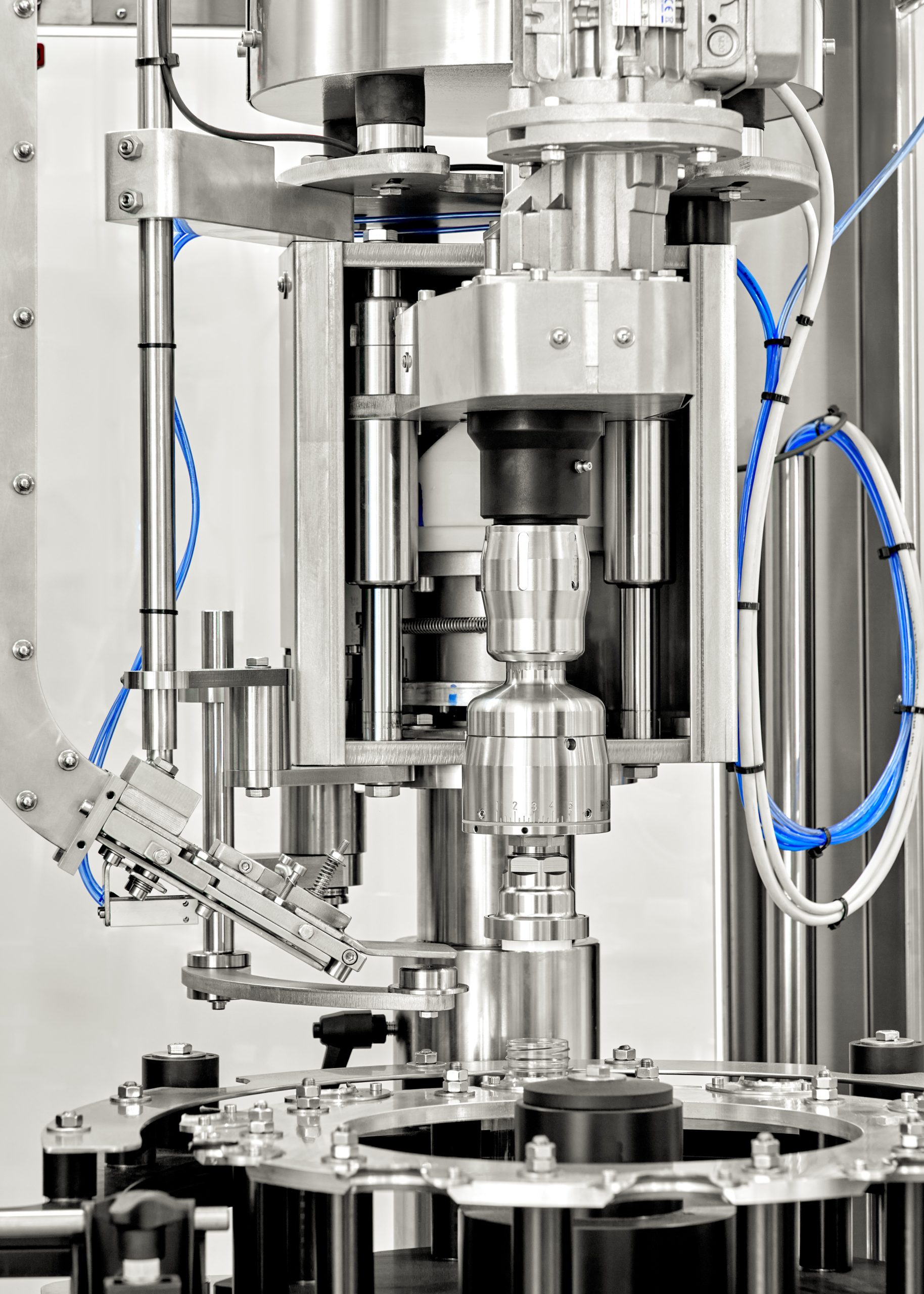

Monoblock system combine high-precision gravitational filling and versatile capping in a single unit, ensuring accurate, consistent fills for various liquids. With options for screw caps, press-on caps, ROPP, Twist-off, and more, the finished bottles are ready for labelling and case packing, streamlining production and saving valuable floor space.

Key Benefits of an Integrated System:

- A wide operational range from 500-2,500 BPH allows you to meet your specific productivity goals and scale with demand.

- A single, synchronized system prevents timing issues common with separate machines, minimizing spillage, reducing product loss, and maximizing uptime.

- The enclosed, easy-to-clean stainless steel design minimizes contamination risk and is ideal for food and beverage applications.

- A central touch-screen lets one operator manage startup, speed adjustments, and format changes, reducing labor costs.

- Machines offer flexible height adjustment and optional parts to accommodate various glass and PET bottle shapes and sizes.

Enhance your Bottling Line with Optional Customizations:

- Modify your system for hot-filling juices, teas, and other beverages that require pasteurization, with heat-resistant components and seals.

- Equip your monoblock with specialized components for gently handling and filling various lightweight PET bottles without deformation.

- A nitrogen dosing unit can be added before or after filling to displace oxygen, preserving freshness, color, and flavor to extend shelf life.

- Add a fully automated washing system with dummy bottles for efficient, repeatable cleaning cycles without disassembly.

- Order extra tooling sets (starwheels, guides) to quickly and easily switch between different bottle shapes and sizes, minimizing downtime.

- Integrate an optional bottle rinsing or air-jet cleaning station at the infeed to create a complete triblock system for maximum product integrity.

The Monoblock system features advanced automation and intelligent sensors to ensure smooth and reliable operation. Its “No Cap, No Seal” detection automatically stops the machine if a cap is missing or incorrectly applied, preventing unsealed products from continuing down the line. Additionally, bottle jam protection uses a photocell at the outlet to detect backups, immediately halting the system to avoid spillage and protect the equipment from damage.

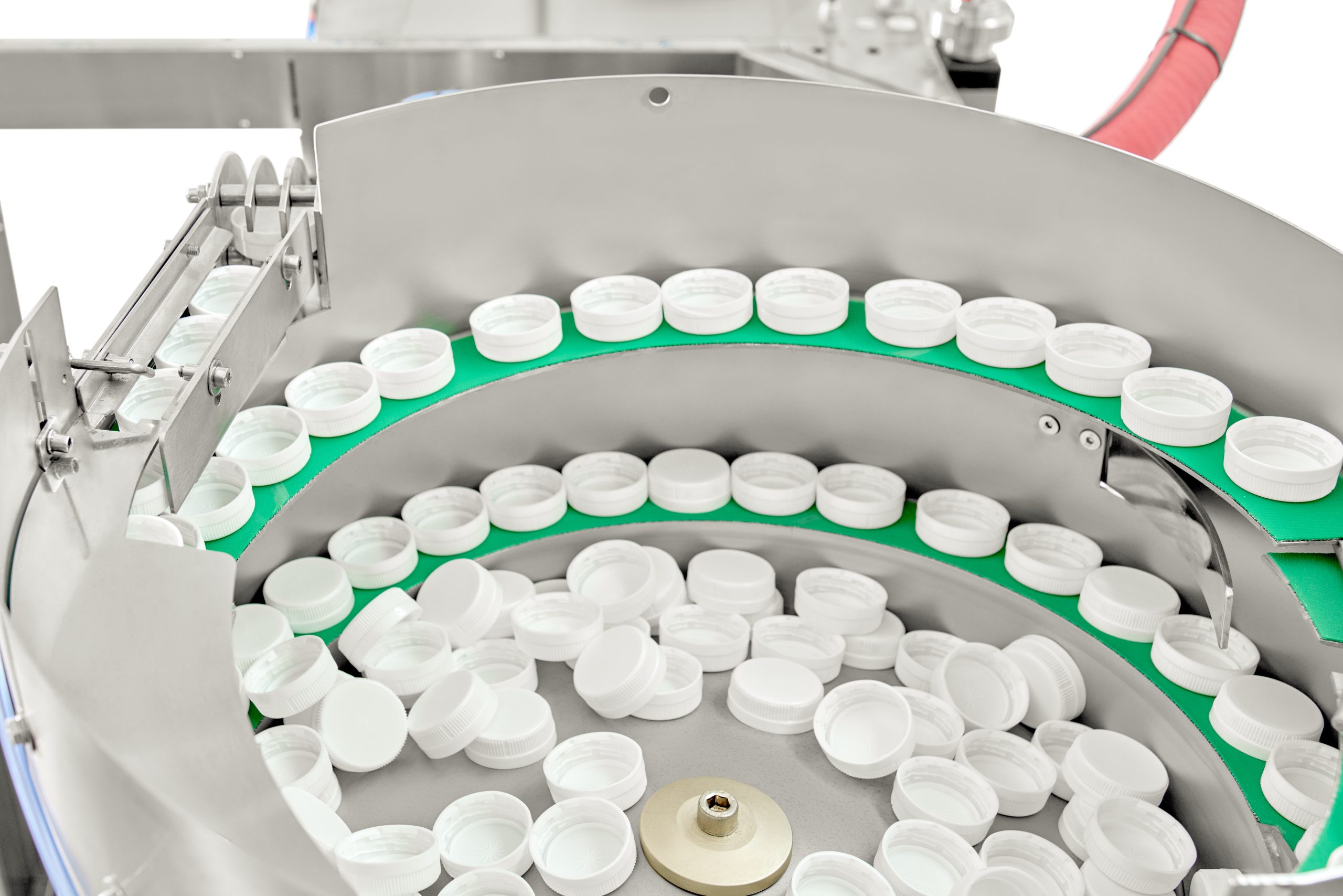

The system can be enhanced with a range of supplementary equipment to optimize production. Custom product pumps, including centrifugal, flexible impeller, or mono pumps, can be selected to match the viscosity and flow requirements of your liquids. An automated cap feeder continuously supplies caps to the capper via a floor-level hopper and elevator, ensuring uninterrupted operation. Additionally, bottle infeed and outfeed tables create a buffer, automate empty bottle handling with a rotary unscrambler, and efficiently accumulate finished products at the line’s end.