Our advanced lyophilization technology is engineered to provide superior drying results for fruits, vegetables, berries, and a wide range of other high-value fruits

By removing moisture at low temperatures under a deep vacuum, our freeze dryers lock in the natural essence and structure of your products, creating premium, shelf-stable goods. Available in a range of sizes from pilot-scale lab units to fully industrial freeze dryers, full FREEZEFRUIT line is designed to grow with your business.

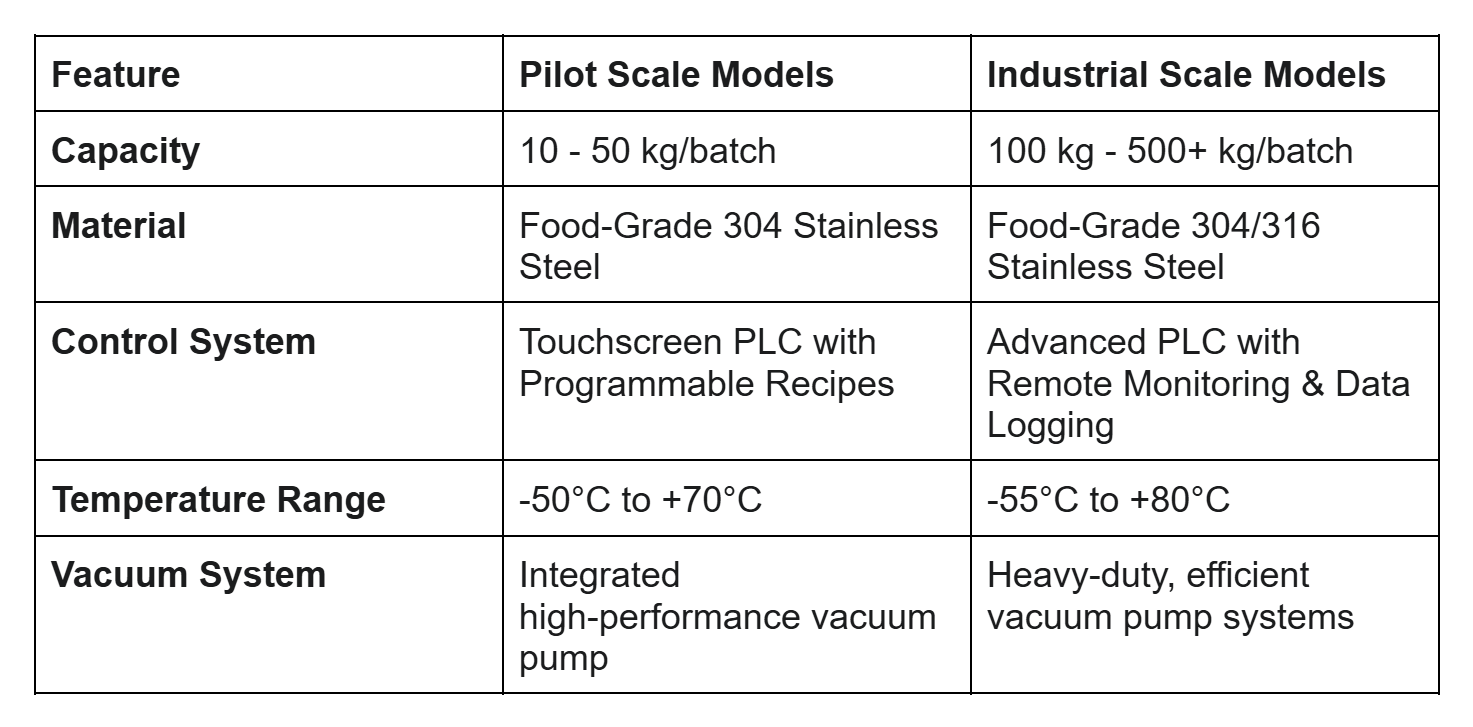

Capacity – 10-50 kg/batch

Key Benefits of FREEZEFRUIT Freeze Dryers:

- Unmatched Quality Preservation – retains over 97% of the original nutrients, vitamins, and enzymes. The process preserves the product’s original shape, size, color, and aroma, creating a visually appealing and high-quality final product.

- Extended Shelf Life – by removing nearly all water content, our freeze dryers create products that are exceptionally stable and can be stored for years without preservatives or refrigeration.

- Versatile Applications – perfect for a diverse range of products, including fruits (berries, bananas, mangoes), vegetables (peas, corn, mushrooms), coffee, dairy, pet treats, and biotech ingredients.

- Quality & Control – features a user-friendly touchscreen interface for precise control over the entire drying process.

- Reliable Construction – built with high-quality stainless steel and robust components to ensure reliability, easy maintenance, and compliance with food processing standards.

- Scalable for Your Needs – from our pilot models for R&D and small batches, to our large, industrial freeze dryers for full-scale commercial production.

Work process:

- Freezing – the product is rapidly frozen to solidify the water content.

- Primary Drying (Sublimation) – the vacuum system lowers the pressure, and a gentle heat is applied, causing the ice to turn directly into vapor without passing through a liquid phase.

- Secondary Drying (Adsorption) – the temperature is slightly raised to remove any remaining unfrozen water molecules.

FREEZEFRUIT model can be customized to meet your demands – for whether it’s for developing new products in a lab or operating alarge-scale food processing facility. Our industrial-scale freeze dryers are engineered for high throughput, energy efficiency, and seamless integration into your production line.