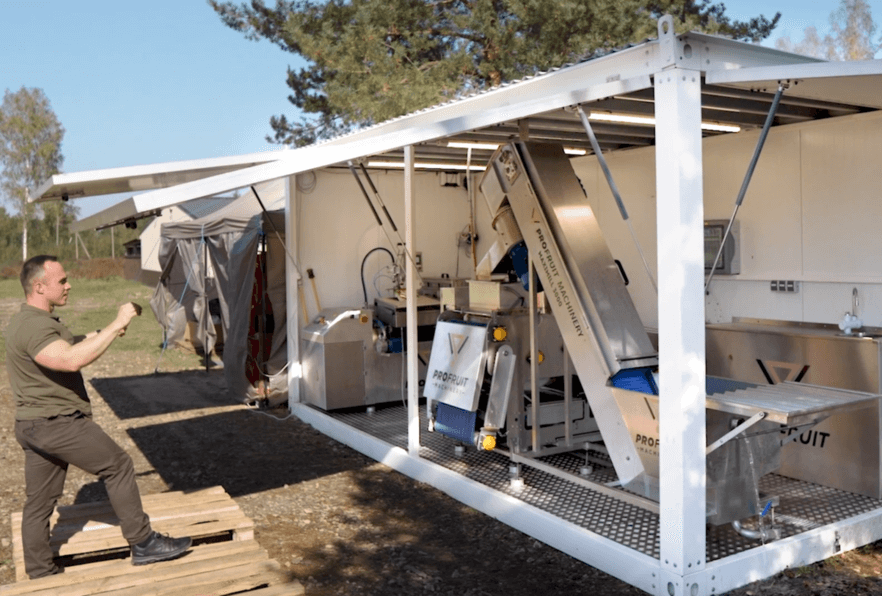

It’s everything we’ve hoped for. It was very good customer service, everything went very smoothly. They were very clear in their instruction—showing us how to clean and work the machines. It’s a big relief to have everything set up now. We look forward to making cider. Thank you so much!

Martin Family Orchard – USA

Rick & John

Co-owners of Martin Family Orchards

Orondo, WA, USA

The Benefits

Cost Savings

Eliminated the need to outsource juice pressing, reducing long-term production costs.

Full In-House Control

Allowed the farm to manage every step of the cider production process on-site, from raw apples to finished product.

High Capacity

Processes up to 1200 kg of apples per hour, enabling efficient use of surplus or cosmetically imperfect apples.

Quick Return on Investment

The line is expected to pay for itself within one year of operation.

New Revenue Streams

Opens up the potential to offer juice pressing services to other local growers in the future.

Dedicated Support

Martin Family Orchards received full on-site setup and training from our ProFruit team. Our experts will continue to provide comprehensive, step-by-step support, and assistance will be even smoother thanks to our partner and official representative in the USA – Scharfenberger Europress, operating directly in the U.S.

juice yield

person for operating

The Client Bought

You can check out the machinery which our client ordered and inspect the details by clicking on any of the products below.

Fruit and Vegetable Washer Elevator Mill MAXIMILL 3000

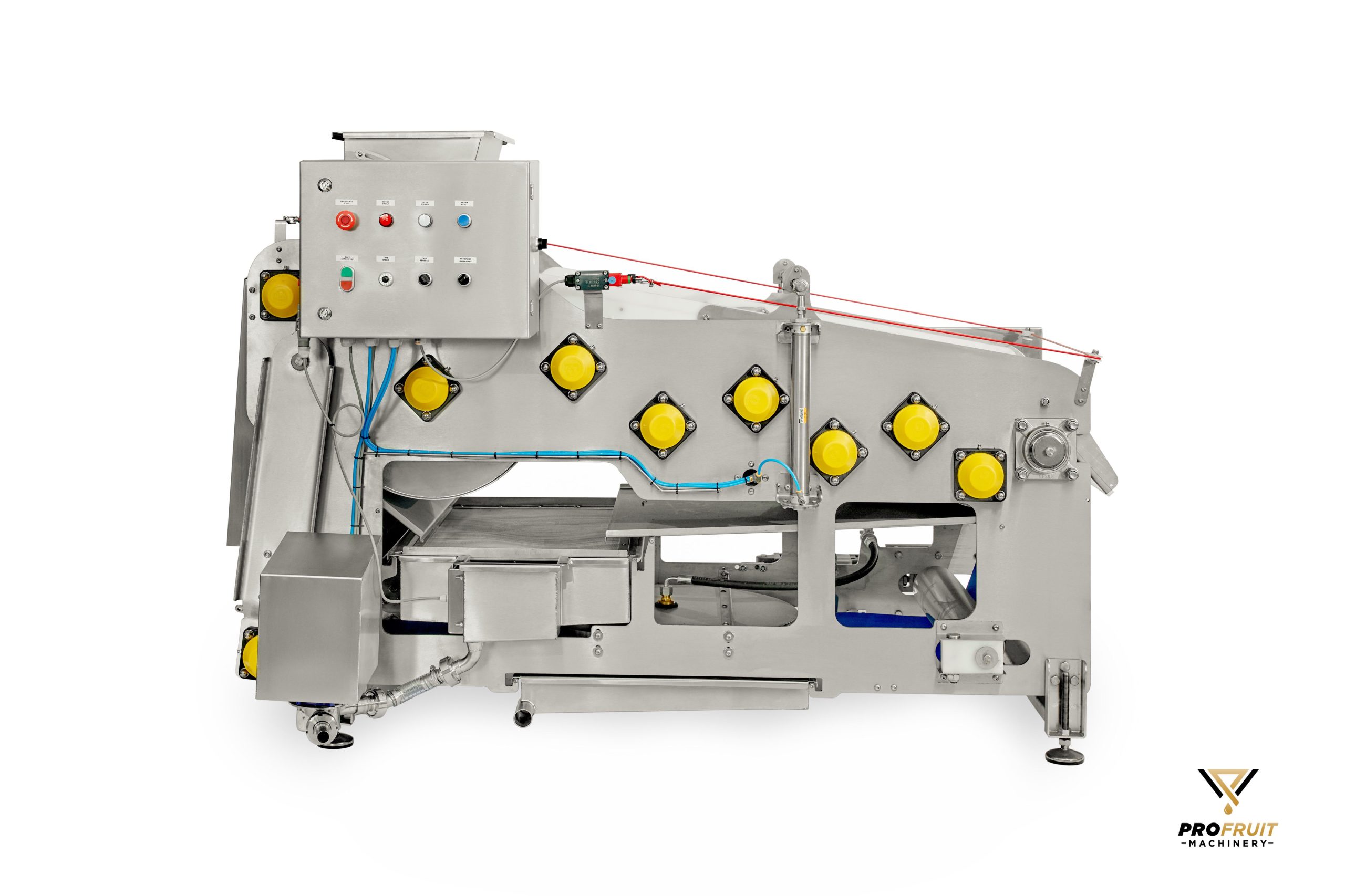

Belt Press POWERPRESS 1200

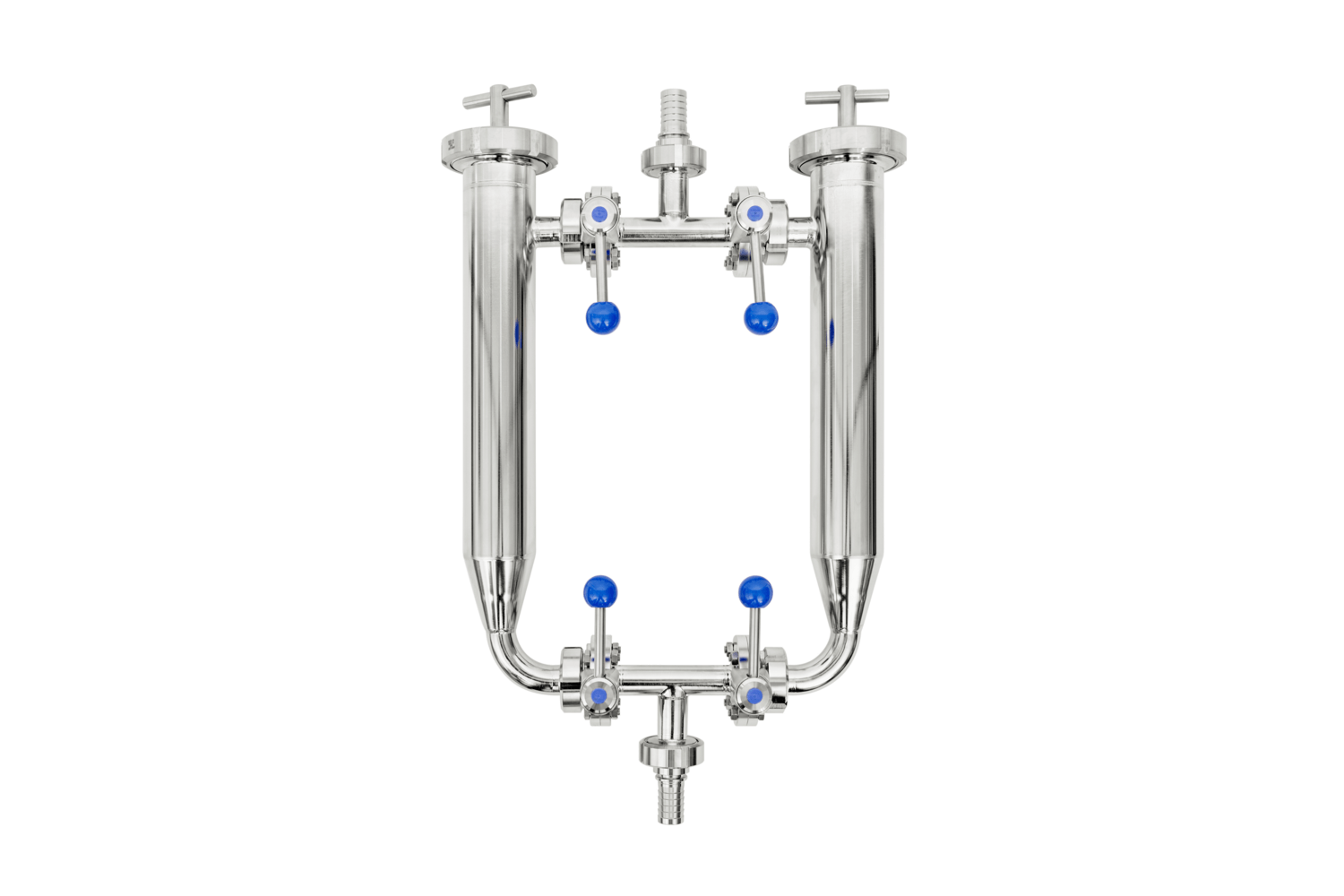

Double Juice Filters

Stainless Steel Tank with Agitator

Diesel/Gas Pasteurizer HEAT 1000

Automatic Bag in Box and Stand up Pouch filler AUTOFLOW

Other Projects

Read the case study articles about our other projects where we customized our fruit processing and filling machinery and provided it to our clients from all over the world.

Glenbourne Cider – Canada

Yablena Natura – Bulgaria

Engin Tarim – Turkey

Engin Tarım cultivates 12 000 decares of apple orchards and 3 500 decares of avocados, producing 55 000 tons of high-quality apples every year. They chose ProFruit for their expantion into apple juice production.